Checklist for Passivation Success: Pre-Project

- Blog

- Checklist for Passivation Success: Pre-Project

Checklist for Passivation Success: Pre-Project

Table of Contents

- Pre-Passivation Preparation: Checklist for Successful Projects

- 7 Critical Steps to Avoid Mistakes During the Passivation Process

- What to Pay Attention to in Passivation Before Starting a Project

- Pre-Passivation Guide for Guaranteed Success: Step-by-Step Control

- Common Issues in Passivation Projects and Prevention Methods

- Analysis of Pre-Project Checks for Successful Passivation

Pre-Passivation Preparation: Checklist for Successful Projects

The passivation process is a critical step in protecting metal surfaces against corrosion, and pre-process preparations are crucial for a successful project. SS-Proje meticulously applies passivation preparation checks to ensure flawless management of the pre-passivation process. These checks enhance workplace safety and guarantee the final product quality.

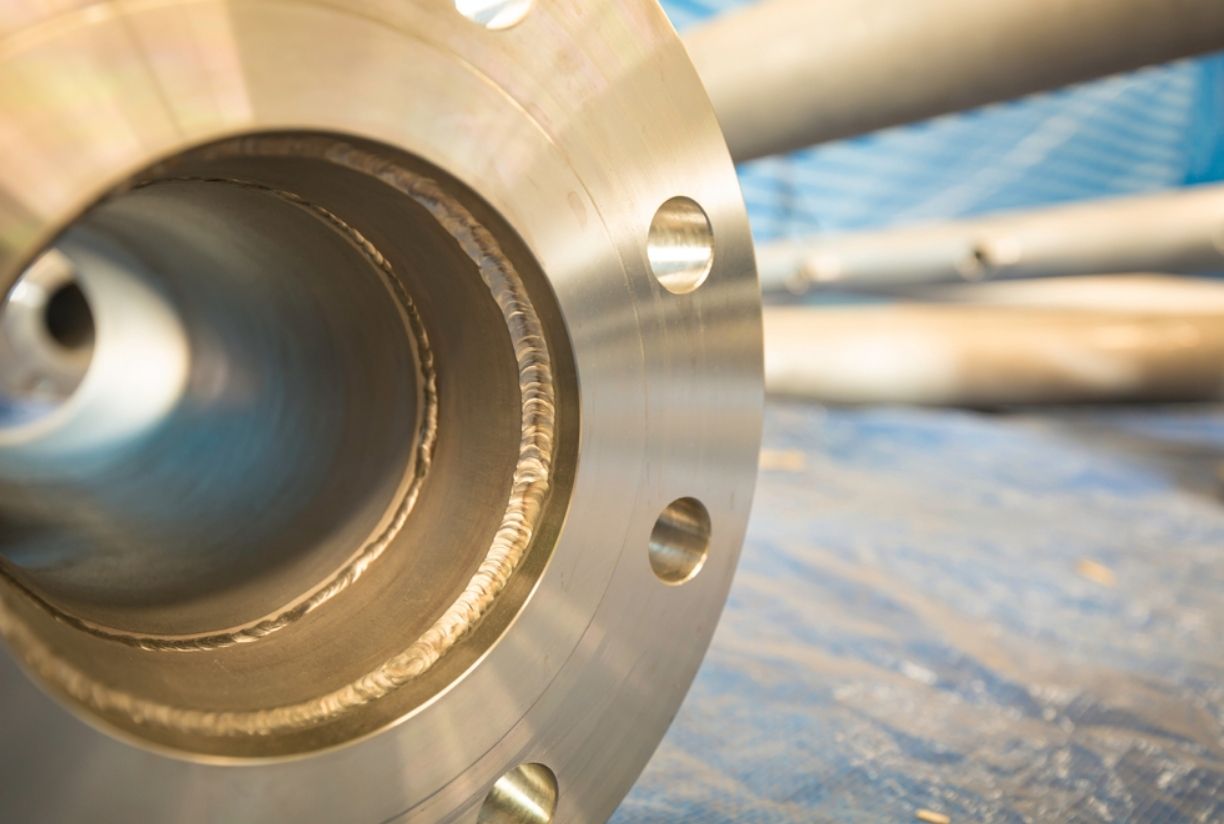

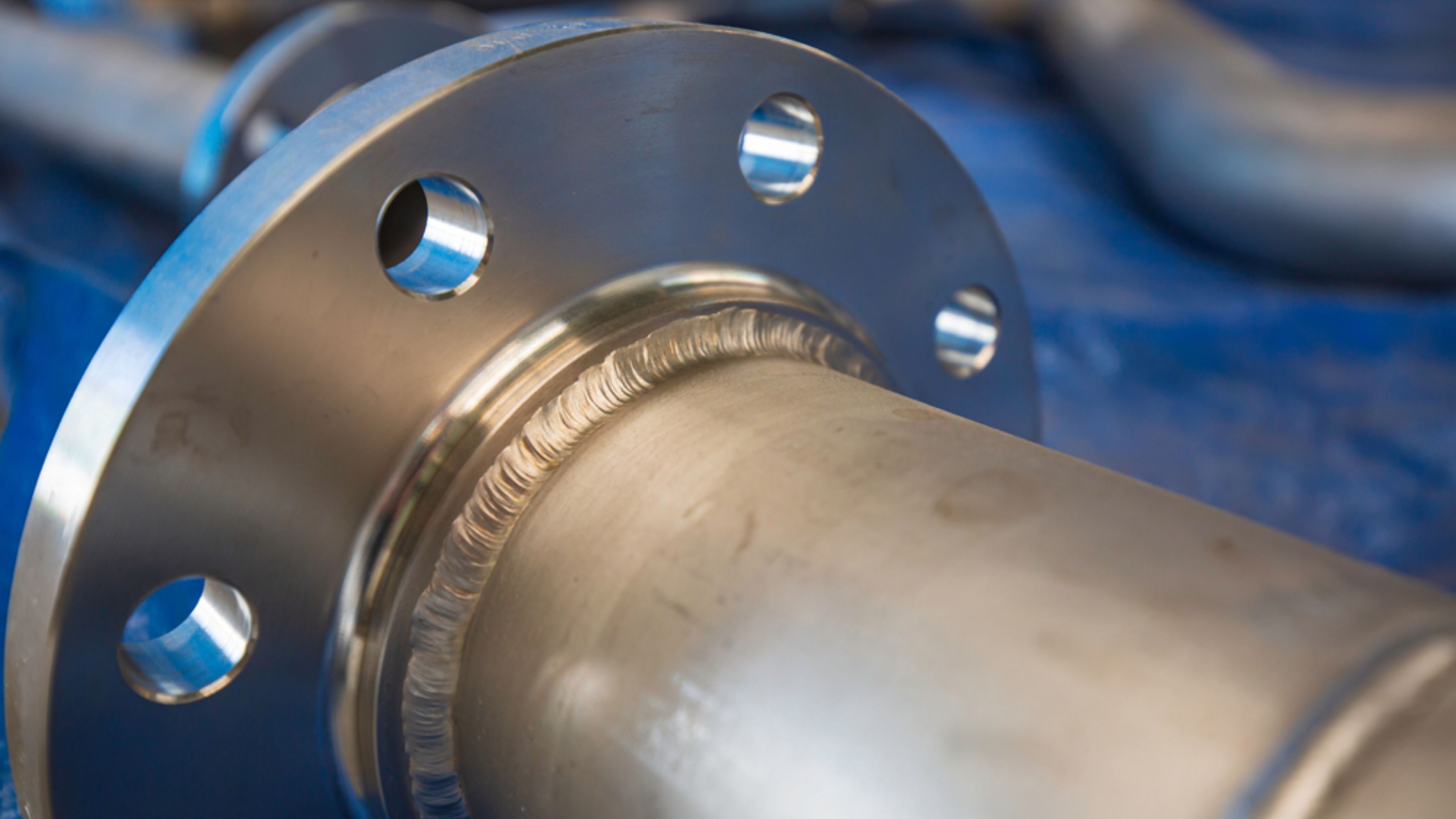

The first step is cleaning and properly preparing the surface. Any remaining oil, dirt, or oxide layers on the surface can reduce the effectiveness of the passivation process. SS-Proje sets standards for metal surface preparation and ensures each step is applied correctly, ensuring the surface is in optimal condition before passivation.

Pre-project material and equipment checks are also a critical part of success. Preparing chemicals in the correct ratios and calibrating equipment helps the process run smoothly. SS-Proje performs passivation equipment checks completely to prevent possible errors and enhance process safety.

Additionally, planning and documenting the steps to be followed throughout the project increases process manageability. SS-Proje keeps records of each stage with a passivation checklist, ensuring projects are completed according to standards. This approach optimizes both quality and time management.

All these steps observed in the pre-passivation preparation process directly affect the durability and longevity of the final product. SS-Proje achieves high success in passivation projects with a comprehensive and systematic project preparation process, ensuring safe and effective results.

7 Critical Steps to Avoid Mistakes During the Passivation Process

The passivation process is critical for increasing the durability of metal surfaces and protecting them against corrosion. However, mistakes during the process can negatively affect both product quality and project efficiency. SS-Proje meticulously applies the steps to follow to achieve flawless results in passivation process management.

First, surface cleaning and preparation are the most critical steps. Any remaining oil, dirt, or oxide layers can reduce passivation effectiveness. SS-Proje applies metal surface preparation standards to ensure the process starts safely and effectively. Additionally, preparing chemicals in correct ratios and applying them at the proper temperature is essential for a flawless process.

Second, equipment checks directly impact process success. SS-Proje verifies the calibration and functionality of each piece of equipment through passivation equipment checks, ensuring the process proceeds continuously and correctly. Third, pre-project documentation and checklists should be prepared; this step helps detect errors in advance and ensures process manageability.

SS-Proje monitors critical parameters such as temperature, duration, and chemical concentration at every stage, providing passivation quality control. Regular inspections and tests are also conducted to identify potential risks in advance. This approach minimizes errors and guarantees consistent project outputs.

Finally, properly following all steps in the passivation process increases product longevity and ensures workplace safety. SS-Proje guarantees high success in projects and optimal performance of metal surfaces with error-free passivation steps.

What to Pay Attention to in Passivation Before Starting a Project

The passivation process is a critical step in enhancing the durability of metal surfaces and protecting them against corrosion. However, preparations made before starting a project play a decisive role in process success. SS-Proje ensures smooth progress of each stage and minimizes errors through pre-passivation checks.

First, surface cleaning and proper preparation form the foundation of the process. Residual dirt, oil, or oxide layers on the metal surface can reduce passivation effectiveness. SS-Proje applies metal surface preparation standards to eliminate these risks. A smooth and homogeneous surface ensures chemicals work effectively.

Second, checking equipment and chemicals is very important. SS-Proje verifies the calibration and functionality of all devices and ensures chemicals are prepared in correct ratios through passivation equipment checks. This guarantees a safe and consistent process.

Third, planning and documenting the steps throughout the process is a critical preparation step. SS-Proje records every stage using a passivation checklist and detects potential disruptions in advance. This approach increases quality and facilitates project management.

All these factors observed before starting the project directly impact passivation success and the longevity of metal surfaces. SS-Proje ensures high success with a comprehensive passivation preparation process and supports safe and effective results.

Pre-Passivation Guide for Guaranteed Success: Step-by-Step Control

The passivation process plays a critical role in protecting metal surfaces against corrosion, and success is directly related to pre-process preparations. SS-Proje applies pre-passivation checks step by step to ensure flawless progress of the pre-passivation process. This approach minimizes errors and guarantees quality at every stage of the project.

A successful passivation process begins with surface preparation. Any remaining oil, dirt, or oxide layers can reduce passivation effectiveness. SS-Proje strictly applies metal surface preparation standards to ensure a homogeneous and clean surface. This preparation supports the effectiveness of chemical applications and long-term durability.

Another critical step is properly checking equipment and chemicals. SS-Proje verifies the calibration of devices and ensures chemicals are prepared at appropriate concentrations through passivation equipment checks. This ensures the process proceeds safely, consistently, and without errors.

Project planning and documentation are also important for success. SS-Proje keeps records of every stage using a passivation checklist and detects potential issues in advance. This systematic approach facilitates project management and helps maintain quality standards.

Carefully applying pre-passivation steps ensures metal surfaces are durable and long-lasting. SS-Proje guarantees high project success and safe results through a comprehensive passivation preparation process.

Common Issues in Passivation Projects and Prevention Methods

Passivation projects are critical for protecting metal surfaces against corrosion. However, common issues during implementation can negatively impact project quality and metal durability. SS-Proje ensures high success by identifying passivation issues in advance and applying effective prevention methods.

One of the most common issues is residues of dirt, oil, or oxide on the surface. Such residues prevent passivation chemicals from properly penetrating the surface and reduce the effectiveness of the protective layer. SS-Proje meticulously applies metal surface preparation steps to eliminate these risks. A homogeneous and clean surface is essential for a smooth process.

Another critical issue is incorrect chemical concentrations or equipment settings. Wrong ratios or miscalibrated equipment can result in ineffective passivation or defective layer formation. SS-Proje ensures all devices work correctly and chemicals are prepared in appropriate concentrations through passivation equipment checks.

Lack of planning and documentation of steps throughout the process can also cause errors. SS-Proje keeps records of every stage using a passivation checklist and identifies potential errors in advance. This systematic approach increases quality and makes projects safer and more manageable.

Proper preparation, equipment checks, and process management are essential to prevent issues in passivation projects. SS-Proje ensures high success and safe results through comprehensive passivation prevention methods.

Analysis of Pre-Project Checks for Successful Passivation

Passivation projects are critical for protecting metal surfaces against corrosion. Common issues during implementation can negatively affect project quality and metal durability. SS-Proje ensures high success by identifying passivation issues in advance and applying effective prevention methods.

One of the most common issues is residues of dirt, oil, or oxide on the surface. These residues prevent passivation chemicals from properly penetrating the surface and reduce the effectiveness of the protective layer. SS-Proje meticulously applies metal surface preparation steps to eliminate these risks. A homogeneous and clean surface is essential for smooth process execution.

Another critical issue is incorrect chemical concentrations or equipment settings. Wrong ratios or miscalibrated equipment can result in ineffective passivation or defective layer formation. SS-Proje ensures all devices operate correctly and chemicals are prepared at proper concentrations through passivation equipment checks.

Lack of planning and documentation of steps throughout the process can also cause errors. SS-Proje records every stage using a passivation checklist and detects potential errors in advance. This systematic approach increases quality and ensures projects are safer and more manageable.

To prevent issues in passivation projects, proper preparation, equipment checks, and process management are essential. SS-Proje ensures high success and safe results through comprehensive passivation prevention methods.