How is the Passivation Coating Process Performed?

- Blog

- How is the Passivation Coating Process Performed?

How is the Passivation Coating Process Performed?

Table of Contents

- What is Passivation Coating and How is it Applied?

- What to Consider During the Passivation Coating Process?

- Which Materials are Suitable for Passivation Coating?

- How is Passivation Coating Applied in Industry?

- Guide to Passivation Coating for Enhancing Material Durability

- Passivation Coating Methods on Different Materials: Advantages and Disadvantages

What is Passivation Coating and How is it Applied?

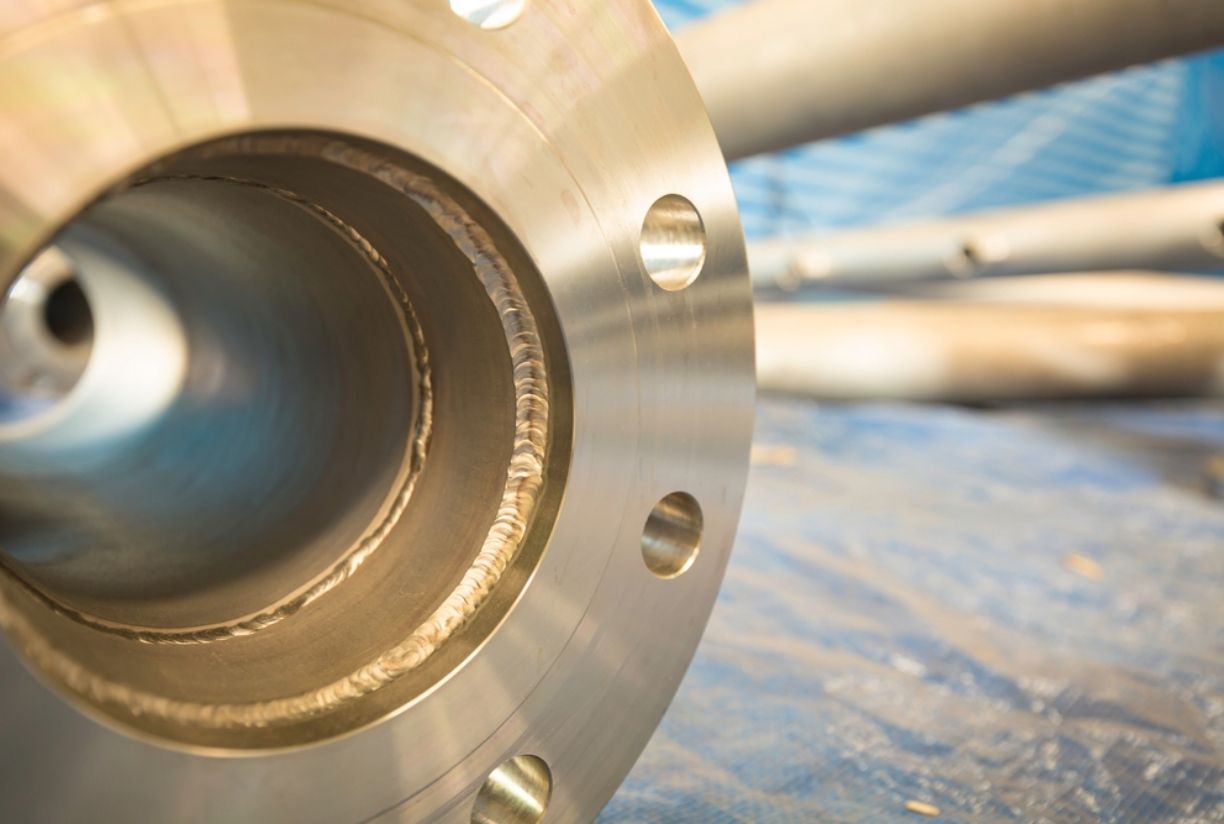

The passivation coating process is applied to metal surfaces to ensure long-lasting durability, and it is especially preferred for stainless steels. This process minimizes the risk of corrosion on the metal surface, extending the lifespan of the material. SS Proje provides solutions tailored to industrial needs with expert teams specialized in passivation coating.

The passivation coating process typically begins with treating the metal surface using special acidic solutions. During this stage, free iron particles on the surface are removed and the oxide layer is strengthened. This layer acts as a natural barrier protecting the metal from external factors. SS Proje prioritizes the quality of materials and process parameters to achieve highly durable results.

Factors such as temperature, solution concentration, and process duration directly affect passivation quality. Incorrect parameters can reduce the coating’s effectiveness and decrease the metal surface’s resistance to corrosion. Therefore, SS Proje implements special control and testing procedures for each project to ensure optimal performance.

After the process, regular maintenance and cleaning of the surface support the long-term effectiveness of the coating. This period is crucial for stainless steel protection and maintaining an aesthetic appearance. SS Proje provides post-coating maintenance guides, enabling users to utilize metal surfaces safely and efficiently.

In industrial production, construction, and various engineering applications, passivation coating is a critical process to enhance metal surface durability and achieve long-lasting products. SS Proje executes this process safely and effectively with extensive industry experience.

What to Consider During the Passivation Coating Process?

The passivation coating process, aimed at increasing metal surface durability and corrosion resistance, involves several critical factors. Surface preparation, selection of correct chemical solutions, and proper control of process parameters directly influence coating effectiveness. SS Proje manages this process according to professional standards to ensure high-quality, long-lasting results.

First, cleaning the surface to be passivated is a critical step. Complete removal of oil, dirt, or metal residues on the surface plays a decisive role in passivation quality. SS Proje uses specialized cleaning techniques to prepare the surface optimally before the process and minimize post-process corrosion risks.

Second, the suitability of the solutions and chemicals used is highly important. Ensuring the correct concentration of acidic solutions, controlling process duration, and monitoring temperature are essential for enhancing coating effectiveness. SS Proje precisely manages these parameters for every project to guarantee surface protection.

Additionally, the surface should be regularly monitored and tested during and after the process. Surface analysis and quality control tests are critical for measuring passivation success. SS Proje validates coating quality with advanced testing methods, ensuring compliance with industrial standards.

After the process, attention to maintenance and usage conditions of metal surfaces supports long-term coating effectiveness. SS Proje’s maintenance recommendations ensure stainless steel protection and aesthetic preservation, allowing users to safely use metal surfaces.

Which Materials are Suitable for Passivation Coating?

Passivation coating is applied to increase corrosion resistance and ensure long-lasting use of metal surfaces. This process is particularly suitable for stainless steel and certain alloyed steel types. SS Proje uses methods and chemical solutions appropriate for the material type to provide maximum durability and quality.

The process works by removing free iron from the surface and strengthening the metal’s natural oxide layer. Therefore, it is effective mainly on corrosion-resistant metals. Besides stainless steel, alloys with high chromium and nickel content are also suitable. SS Proje analyzes different alloys to determine the optimal process parameters for each material and ensures safe application.

Passivation coating is also preferred for surfaces requiring aesthetics and hygiene. For example, stainless metal equipment used in food and medical industries becomes both long-lasting and less prone to microbial accumulation thanks to passivation. SS Proje offers specialized solutions for such sectors, ensuring both durability and safe usage of metal surfaces.

The applicability of passivation coating depends directly on the chemical composition and usage conditions of the material. Surface preparation, correct chemical selection, and control of process parameters are critical for passivation success. SS Proje carefully manages all stages to deliver industrial-standard, high-quality coatings.

Passivation coating applied to different metals and alloys enhances durability, ensuring reliability and performance in industrial applications. SS Proje offers tailored passivation solutions for every material type with its experienced team and sector knowledge.

How is Passivation Coating Applied in Industry?

Industrial passivation coating is a critical process applied to increase corrosion resistance and extend the lifespan of metal surfaces. It is particularly effective for stainless steel and alloyed metals. SS Proje implements these applications at industrial scale with high-quality standards, ensuring metal surface durability.

The process starts with the chemical removal of free iron from the surface and strengthening the natural oxide layer. Surface preparation is crucial for passivation success. SS Proje cleans oils, dirt, and metal residues to ensure a smooth process. This step maximizes corrosion-preventive effects.

Selection of chemical solutions and control of process parameters are another critical step. Correct solution concentration, precise process duration, and temperature adjustment ensure optimal metal protection. SS Proje uses specialized formulas and protocols for each metal type, securing passivation quality.

During and after passivation, the surface should be regularly tested. Surface analysis and quality control tests verify corrosion resistance. SS Proje guarantees effectiveness and compliance with industrial standards using advanced analysis techniques.

Industrial passivation coating not only enhances metal durability but also preserves aesthetics and ensures hygienic use. SS Proje’s extensive experience manages industrial passivation processes, providing high performance and reliability across all metal applications.

Guide to Passivation Coating for Enhancing Material Durability

Increasing material durability is critical in industrial production and manufacturing for long-lasting and reliable performance. Passivation coating plays a key role in this process. SS Proje provides professional passivation services to enhance corrosion resistance and extend the lifespan of metal surfaces, particularly stainless steel and alloyed metals.

The passivation process begins with surface cleaning and removal of free iron. Eliminating dirt, oil, and metal residues directly affects effectiveness. SS Proje uses advanced cleaning techniques to maximize corrosion resistance. Surface preparation is a key factor for long-lasting coating.

Chemical solutions are selected according to the metal type. Correct solution concentration and precise control of process duration are crucial for passivation quality. SS Proje applies high-standard protocols for different metal groups to maximize surface protection.

After passivation, surfaces must be regularly tested. Surface analysis and quality control tests verify corrosion resistance and ensure compliance with industrial requirements. SS Proje uses advanced testing methods to meticulously monitor post-process quality.

Passivation coating enhances durability, preserves aesthetic appearance, and ensures hygienic usage. SS Proje’s expertise provides reliable, long-lasting solutions across all metal applications.

Passivation Coating Methods on Different Materials: Advantages and Disadvantages

Passivation coating is critical for increasing corrosion resistance and extending durability. Methods vary depending on material type and usage purpose. SS Proje offers optimized passivation solutions for stainless steel, alloyed metals, and specialized industrial materials, maximizing the advantages of each method.

For stainless steels, passivation is generally performed using acidic solutions. This method removes free iron on the surface, enhancing metal surface durability and preventing oxidation. Advantages include high corrosion resistance and long lifespan; disadvantages include the need for careful control of chemical solutions and slight potential impact on surface shine.

Aluminum and alloyed metals require different passivation techniques, important for surface protection and aesthetics. Advantages include increased durability without compromising lightness; disadvantages may include longer process times and higher costs for certain chemical combinations.

SS Proje determines suitable passivation protocols for each material and applies the process meticulously. Pre-treatment, proper chemical selection, and post-process quality control ensure coating effectiveness. This strengthens metal surface durability and guarantees long-term industrial performance.

Analyzing advantages and disadvantages of different methods allows SS Proje to deliver reliable and effective protection across various metal surfaces.