Industrial Assembly Services Including Assembly, Testing and Commissioning.

- Blog

- Industrial Assembly Services Including Assembly, Testing and Commissioning.

Industrial Assembly Services Including Assembly, Testing and Commissioning.

Table of Contents

- The Impact Of Integrated Installation Testing And Commissioning On Reducing Startup Delays

- Critical Stages In Industrial Installation And Commissioning For Equipment Lifetime And ROI

- A Cost Benefit Analysis Of In House And Professional Installation Services For Quality Speed And Facility Efficiency

- A Project Manager Guide To Risk Reduction And Compliance Through Factory Acceptance Testing And Site Acceptance Testing

- Achieving Energy Savings And Sustainable Performance From Day One With Professional Commissioning

- Ensuring Regulatory Compliance And Scalable Production Through End To End Installation And Validation Protocols

- The Effect Of Automated System Testing During Commissioning On Maintenance And Operational Downtime Costs

The Impact Of Integrated Installation Testing And Commissioning On Reducing Startup Delays

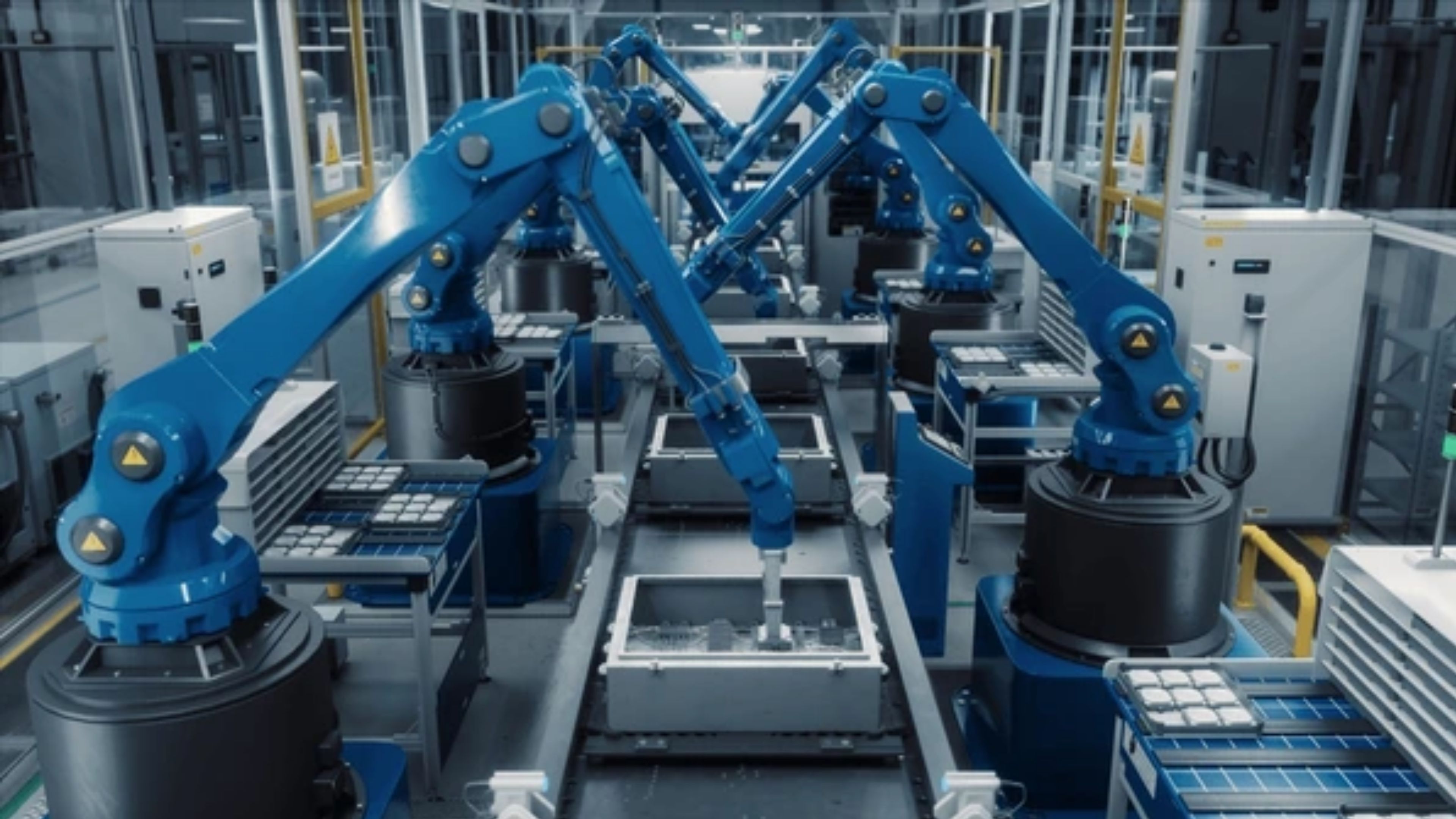

For any capital project, the transition from installation to full-scale production is a period of significant financial risk, where startup delays directly impact ROI and market opportunities. Integrated industrial assembly and commissioning services are engineered to eliminate this friction by managing the entire lifecycle from component integration to operational handover. This seamless approach, a cornerstone of advanced process optimization engineering, ensures that complex systems achieve nameplate capacity faster and with guaranteed reliability, turning a potential bottleneck into a competitive advantage.

The process begins with meticulous tank and mixer assembly and other industrial equipment installation, where precision alignment and connection are verified against design specifications. This foundational accuracy is critical for preventing the vibrational issues and premature wear that plague poorly assembled systems. Following physical integration, rigorous factory acceptance testing FAT protocols are executed to validate individual unit performance before they become part of the larger process train, identifying and resolving defects in a controlled environment rather than on the active production floor.

Commissioning is where the integrated system is proven as a whole, a phase dedicated to achieving operational reliability commissioning. This involves calibrating instruments, tuning control loops, and performing dry and wet runs to simulate actual production conditions. This methodical validation, often overseen by a dedicated project consultancy for compliance, ensures that every interaction between components—such as a pump and a filter skid—functions harmoniously. Specialized firms like SS Proje leverage this phase to embed energy-efficient setpoints and operational best practices from the outset.

The ultimate value of this integrated approach is measured in operational readiness and long-term performance. A system that is properly assembled, tested, and commissioned experiences minimal infant mortality failures, leading to extended equipment life and radically reduced maintenance costs during its most critical early years. This disciplined methodology is essential for delivering sustainable facility performance and is a defining feature of comprehensive SS Proje technical solutions.

By investing in professional assembly and commissioning, facility owners secure not just a functioning system, but a optimized asset capable of delivering its intended return from day one. The avoidance of costly startup delays, the assurance of regulatory compliance, and the foundation of reliable, efficient operation create a compelling financial case. This proactive investment in quality and validation is the most effective strategy for mitigating risk and ensuring a new facility or line upgrade becomes a immediate contributor to profitability and growth.

Critical Stages In Industrial Installation And Commissioning For Equipment Lifetime And ROI

A disciplined, phased approach to industrial assembly and commissioning services is the most effective strategy for transforming capital expenditure into long-term, high-yield operational assets. This structured methodology ensures that every stage, from initial component receipt to final performance validation, is executed with precision, directly contributing to maximized equipment lifespan and a superior return on investment. This systematic process is fundamental to achieving true process optimization engineering and is a hallmark of professional SS Proje technical solutions.

The first phase involves meticulous pre-assembly planning and inspection, verifying that all components, such as those for tank and mixer assembly, meet specified material and dimensional standards before integration begins. This proactive quality gate prevents the installation of substandard parts that could lead to premature failure. The second phase is the precision industrial equipment installation itself, where alignment, torque, and connection integrity are strictly controlled to prevent the misalignments and stresses that cause excessive wear and energy loss over time.

The third critical phase is pre-commissioning checks and factory acceptance testing FAT, where individual systems are validated for mechanical and basic electrical function. This step isolates and resolves issues before complex integration, saving considerable time and cost. The fourth phase, full system commissioning, is the core of operational reliability commissioning, where the entire process is tested under simulated production conditions to fine-tune performance and ensure all components work in harmony.

The fifth and final phase is performance qualification and handover, which includes operator training and the creation of baseline documentation for future maintenance. This phase often benefits from expert project consultancy for compliance to ensure all regulatory requirements are met and documented. The collective outcome of these five phases is a facility primed for sustainable facility performance, with systems that operate at peak efficiency from day one.

By adhering to this rigorous five-phase protocol, industrial operations can confidently expect a significant extension in asset service life, a drastic reduction in unscheduled downtime, and optimal energy consumption. This methodical approach not only safeguards the initial investment but also establishes a foundation for continuous, cost-effective production. It is the definitive pathway to achieving the operational excellence and long-term profitability that define world-class industrial facilities.

A Cost Benefit Analysis Of In House And Professional Installation Services For Quality Speed And Facility Efficiency

The decision between utilizing in-house labor and engaging professional industrial assembly and commissioning services is a strategic calculation that extends far beyond initial labor costs. While an internal team may appear cost-effective, a thorough analysis must weigh the hidden expenses of delayed startups, rework, and long-term equipment performance against the value of expert execution. This evaluation is critical for achieving true process optimization engineering and securing the intended return on a capital investment.

Quality and precision are the primary differentiators, directly impacting equipment longevity and operational reliability. Professional services bring specialized tooling, calibrated torque wrenches, and standardized procedures for tasks like tank and mixer assembly, ensuring perfect alignment and connection integrity that prevents vibrational damage and premature wear. This level of precision in industrial equipment installation is difficult to replicate with a general-purpose maintenance crew, and the resulting quality directly translates to reduced maintenance costs and extended asset life.

Project speed and risk mitigation are equally significant factors. A dedicated external team, such as those providing SS Proje technical solutions, works exclusively on the project, avoiding the distractions that often delay in-house staff. They also implement rigorous factory acceptance testing FAT and operational reliability commissioning protocols, systematically identifying and resolving issues before they cause costly production interruptions. This proactive approach, often supported by project consultancy for compliance, ensures regulatory adherence from the outset.

The long-term benefits crystallize in sustained sustainable facility performance. A professionally assembled and commissioned system operates at peak energy efficiency from day one, with optimized pump curves and control settings that lower utility costs for the life of the equipment. The avoidance of installation errors means minimal unplanned downtime and a much higher degree of operational predictability, which is invaluable for meeting production targets and maintaining supply chain commitments.

Ultimately, the higher initial investment in professional assembly services is justified by a significantly lower total cost of ownership. The combined value of faster time-to-revenue, guaranteed quality, reduced operational risk, and long-term efficiency gains delivers a far superior financial outcome. For facilities focused on maximizing lifespan, reliability, and profitability, partnering with experts is not an expense but a strategic investment in operational excellence.

A Project Manager Guide To Risk Reduction And Compliance Through Factory Acceptance Testing And Site Acceptance Testing

For project managers in highly regulated industries, structured Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) are not optional checkboxes but fundamental risk management tools. These validated protocols form the critical bridge between equipment manufacture and successful industrial equipment installation, systematically identifying and resolving defects before they can impact production schedules or product quality. Integrating rigorous factory acceptance testing FAT into your industrial assembly and commissioning services strategy is a proactive measure that safeguards capital investment and ensures contractual obligations are met.

The FAT process is conducted at the supplier's facility, allowing for a comprehensive evaluation of individual units like those for tank and mixer assembly before shipment. This stage verifies materials of construction, dimensional accuracy, mechanical function, and basic control logic against the purchase specification. Identifying a non-conformance at this point, with the vendor's resources readily available, is exponentially faster and cheaper than discovering the same issue after delivery, preventing costly delays during the main operational reliability commissioning phase.

SAT occurs after installation at the final site, confirming that the equipment has been transported, installed, and integrated correctly and that it functions as intended within its operating environment. This test validates connections to utilities, interfaces with other plant systems, and performance under actual load conditions. A well-executed SAT, often guided by a project consultancy for compliance, provides the documented evidence required for regulatory audits and is a cornerstone of reliable sustainable facility performance.

The cumulative benefit of FAT and SAT is a dramatic reduction in project risk and a significant acceleration of the time-to-revenue curve. By catching errors early, project managers avoid the domino effect of delays, cost overruns, and potential compliance failures. This disciplined approach is a key component of advanced process optimization engineering and is a standard practice within comprehensive SS Proje technical solutions, ensuring that systems are proven to perform before they are relied upon for production.

Ultimately, viewing FAT and SAT as strategic investments rather than project overhead is essential for modern facility management. The documentation generated provides a baseline for future maintenance and performance benchmarking, while the confidence gained in system reliability allows for aggressive production scheduling. This methodical validation process is the most effective way to ensure a new asset delivers its promised efficiency, compliance, and profitability from the moment it is switched on.

Achieving Energy Savings And Sustainable Performance From Day One With Professional Commissioning

Professional commissioning is the strategic catalyst that transforms a static installation into a dynamically optimized production asset, delivering measurable energy savings, process refinement, and sustainable performance from the very first operating cycle. This critical phase goes beyond simple functional verification, embedding efficiency into the core of operations through systematic tuning and validation. For project managers, it represents the culmination of industrial assembly and commissioning services, where the theoretical benefits of a design are converted into tangible operational gains, establishing a foundation for superior sustainable facility performance.

The journey to energy efficiency begins with precise calibration during operational reliability commissioning. Commissioning engineers fine-tune variable frequency drives (VFDs) on pumps and agitators, optimize temperature setpoints on heat exchangers, and validate control loops to ensure systems use the minimum energy required for the task. This meticulous adjustment, often applied after a successful factory acceptance testing FAT and industrial equipment installation, eliminates energy waste that would otherwise become a permanent operational cost, directly contributing to the goals of advanced process optimization engineering.

Process optimization is achieved by testing the integrated system under real-world conditions, identifying and resolving bottlenecks that limit throughput or quality. For example, during the commissioning of a complex tank and mixer assembly, engineers may adjust agitation speeds or sequences to achieve perfect homogeneity without damaging product or consuming excess power. This holistic tuning ensures all components work in synergy, maximizing overall equipment effectiveness (OEE) and ensuring the facility operates at its designed capacity without unnecessary stress on individual assets.

This rigorous approach is essential for compliance and longevity, benefits often underscored by a dedicated project consultancy for compliance. The comprehensive documentation generated during commissioning provides auditable proof that systems perform as intended, satisfying regulatory requirements. Furthermore, by verifying that equipment operates within its design parameters, professional commissioning prevents the undue wear and tear that leads to premature failure, as consistently demonstrated in robust SS Proje technical solutions.

Investing in professional commissioning is therefore a direct investment in long-term profitability and environmental stewardship. The immediate energy savings and process improvements create a rapid return, while the extended equipment life and reduced risk of compliance violations secure the asset's value for years to come. By leveraging this disciplined final phase, facilities can ensure they are not just operational, but optimally efficient, compliant, and sustainable from the moment production begins.

Ensuring Regulatory Compliance And Scalable Production Through End To End Installation And Validation Protocols

In regulated industries, achieving and maintaining compliance while simultaneously enabling scalable production growth presents a complex operational challenge. End-to-end assembly and validation protocols provide a structured framework to master this duality, ensuring that every stage from component receipt to final performance qualification is documented, auditable, and designed for future expansion. This holistic approach to industrial assembly and commissioning services is essential for building facilities that are both compliant today and adaptable for tomorrow's demands, a key objective of strategic process optimization engineering.

The foundation of compliance is laid during the initial industrial equipment installation and assembly phases. For critical systems like tank and mixer assembly, this means verifying material certifications, weld logs, and surface finish reports against Good Manufacturing Practice (GMP) standards. Following this, factory acceptance testing FAT serves as the first major compliance gate, generating documented evidence that equipment functions to specification before it ever leaves the factory, a process greatly enhanced by engaging a project consultancy for compliance.

Scalability is engineered into the process through modular design and comprehensive testing. During operational reliability commissioning, systems are not only tested at baseline conditions but also at projected future capacities to validate their performance headroom. This proactive stress-testing identifies potential bottlenecks early, allowing for cost-effective modifications before production scaling begins. This forward-looking methodology is a defining feature of integrated SS Proje technical solutions, which prioritize long-term flexibility alongside immediate performance.

The synergy between compliance and scalability culminates in a facility capable of sustainable facility performance. The rigorous documentation trail from assembly through commissioning satisfies auditor requirements, while the proven system headroom allows for confident production increases without regulatory re-qualification delays. This integrated approach minimizes the validation burden for future product lines or capacity expansions, turning compliance from a barrier into a business enabler.

By investing in end-to-end protocols, industrial leaders secure a significant competitive advantage. The ability to rapidly scale production within a fully compliant framework accelerates time-to-market for new products and maximizes return on capital assets. This strategic approach to project execution is the most reliable path to building a resilient, efficient, and future-proof industrial operation that thrives in a dynamic regulatory and market landscape.

The Effect Of Automated System Testing During Commissioning On Maintenance And Operational Downtime Costs

Automated system testing represents a paradigm shift in the commissioning phase, transforming it from a manual, sample-based verification into a comprehensive, data-driven validation process. This advanced methodology is a critical component of modern industrial assembly and commissioning services, designed to proactively identify latent defects and performance deviations that would otherwise manifest as costly failures during production. By rigorously exercising every control sequence, safety interlock, and operational mode, automated testing is the most effective strategy for preventing unplanned downtime and establishing a baseline for sustainable facility performance.

The process begins by extending the principles of factory acceptance testing FAT to the fully integrated system after industrial equipment installation. Scripted tests automatically cycle equipment through its entire operational range, validating the performance of complex assemblies like a tank and mixer assembly under simulated load conditions. This exhaustive testing uncovers issues such as faulty sensors, programming errors in PLCs, or mechanical resonances that manual checks might miss, enabling corrections before the system impacts valuable production batches.

The direct impact on maintenance costs is profound. By identifying and rectifying infant mortality failures during commissioning, automated testing eliminates the frequent call-outs and reactive repairs that characterize a system's early operational life. This contributes significantly to operational reliability commissioning by ensuring the equipment is genuinely ready for continuous operation. The data collected also serves as a pristine performance baseline for future predictive maintenance, allowing technicians to spot deviations from optimal conditions long before a breakdown occurs.

This rigorous approach is integral to a holistic process optimization engineering strategy and is a standard practice within advanced SS Proje technical solutions. The comprehensive test reports generated provide undeniable evidence for project consultancy for compliance requirements, demonstrating to regulators that every system function has been validated. This not only speeds up the approval process but also builds a foundation of compliance that reduces audit risks for years to come.

Investing in automated system testing during commissioning is a strategic decision that pays continuous dividends throughout the asset's lifecycle. The upfront investment in thorough validation is offset many times over by the avoidance of a single major production stoppage. This proactive approach ensures that a facility launches with confidence, operates with exceptional reliability, and maintains a lower total cost of ownership, solidifying its competitive position through unparalleled operational consistency.