Installation Site Preparation: Avoid Project Delays

- Blog

- Installation Site Preparation: Avoid Project Delays

Installation Site Preparation: Avoid Project Delays

Table of Contents

- Assembly Site Preparation Guide: Minimize Project Delays

- 7 Critical Steps to Prevent Delays in Site Assembly

- Pre-Assembly Checklist for Project Success: How Should Site Preparation Be?

- Common Issues During Assembly and Preventive Strategies

- Ways to Increase Efficiency in Assembly Through Site Preparation

- Pre-Assembly Planning: Effective Tactics to Prevent Project Delays

Assembly Site Preparation Guide: Minimize Project Delays

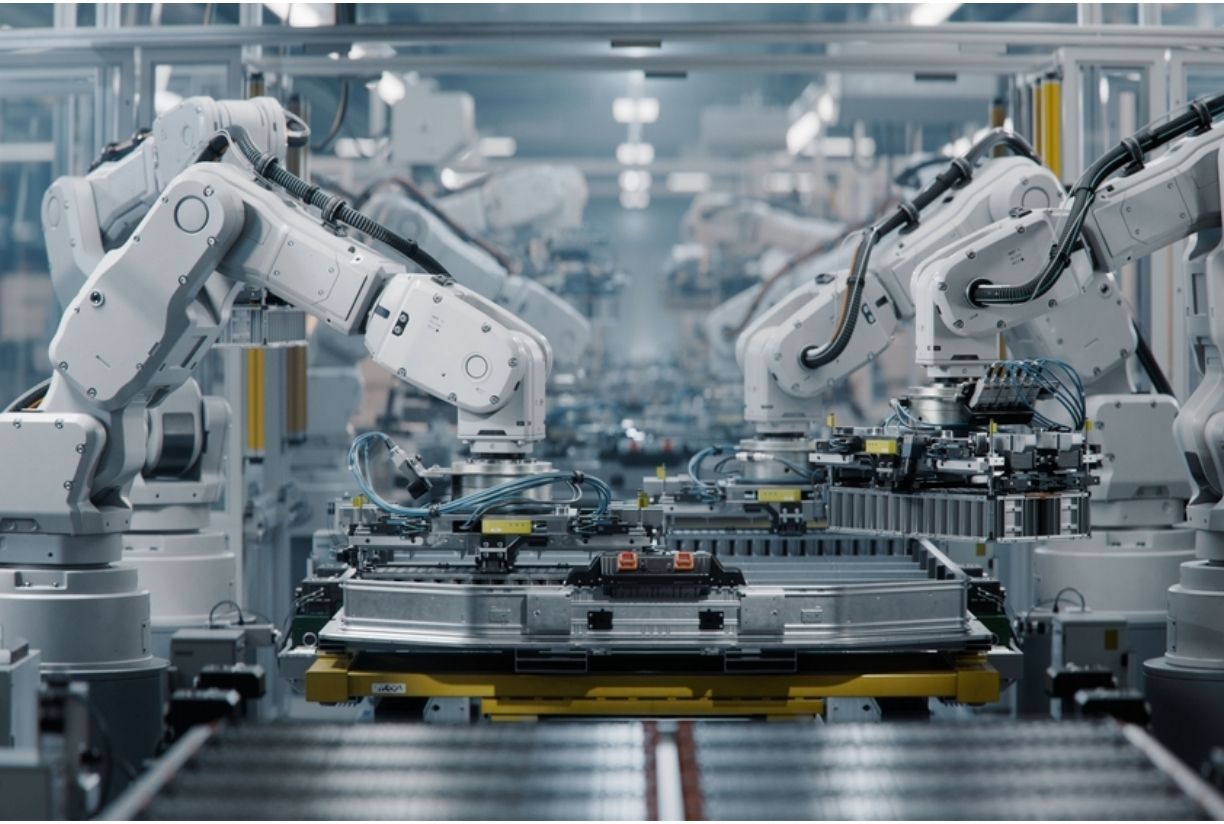

Assembly site preparation is a critical step to ensure projects are completed on time and without issues. SS-Proje minimizes project delays through meticulous planning and control steps in the assembly site preparation process. Proper preparation enhances equipment efficiency while supporting workplace safety.

Before starting a project, a detailed analysis of site conditions must be conducted. Factors such as ground condition, electrical and water infrastructure, and material storage areas directly affect the speed and accuracy of assembly. SS-Proje meticulously inspects these elements through site preparation checks and takes necessary precautions. This prevents potential disruptions during assembly.

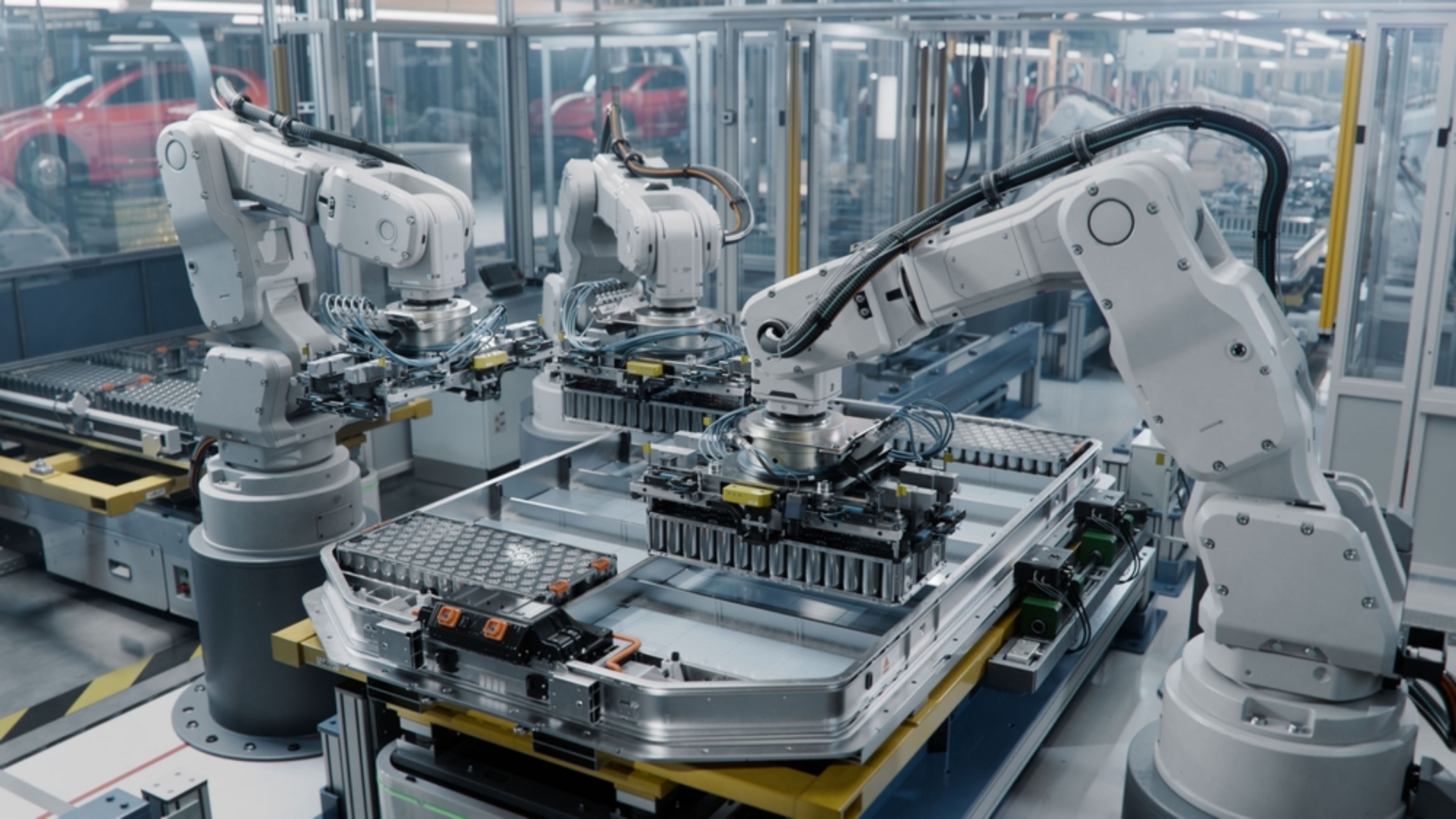

Equipment and material management is also a critical part of site preparation. SS-Proje verifies that all tools and equipment are operational through assembly equipment checks and ensures necessary materials are available on-site. This approach allows workflow to continue uninterrupted and helps maintain the project schedule.

Planning and coordination are other key factors that enhance site preparation effectiveness. SS-Proje documents each step and tracks processes using a project checklist, anticipating possible delays and taking preventive action. This method improves quality and minimizes time losses in the project.

Assembly site preparation prevents project delays and ensures high efficiency through proper planning, equipment checks, and process monitoring. SS-Proje guarantees smooth and timely project completion with comprehensive site preparation steps.

7 Critical Steps to Prevent Delays in Site Assembly

Delays in site assembly are among the most common issues that increase project costs and disrupt workflow. SS-Proje ensures timely and smooth project progress through 7 critical steps to prevent site assembly delays. These steps cover the entire process, from planning to equipment checks, and increase efficiency.

The first step is a detailed evaluation of site conditions. Pre-checking factors such as ground condition and electrical and water infrastructure prevents potential disruptions. SS-Proje ensures the site is ready for assembly and minimizes risks through site preparation checks.

The second step is equipment and material management. SS-Proje verifies that all tools and equipment are operational and ensures required materials are available on-site through assembly equipment checks. This supports uninterrupted workflow.

Thirdly, process planning and coordination are critical. SS-Proje documents each step using a project checklist, anticipates potential delays, and intervenes as needed, ensuring adherence to the project schedule.

Communication and internal team coordination also play a vital role in preventing delays. SS-Proje facilitates effective information flow between the site team and office, ensuring each step proceeds in harmony. Risk analysis and preventive measures provide rapid solutions to unexpected issues.

Preventing delays in site assembly is possible through proper planning, equipment and material checks, systematic process management, and effective communication. SS-Proje guarantees timely and smooth project completion with comprehensive site assembly steps.

Pre-Assembly Checklist for Project Success: How Should Site Preparation Be?

Timely and smooth project completion depends on proper pre-assembly site preparation. SS-Proje carefully evaluates all elements on-site through a pre-assembly checklist to prevent potential delays. Proper planning, equipment, and material checks enhance project success.

The first step is a detailed examination of site conditions. Factors such as ground level, electrical and water infrastructure, and material storage areas directly affect assembly efficiency. SS-Proje inspects all these elements and ensures necessary adjustments through site preparation checks.

Equipment and material management is a critical part of pre-assembly preparation. SS-Proje guarantees all tools and equipment are complete and operational and ensures required materials are on-site through assembly equipment checks. This supports uninterrupted workflow.

Planning and coordination further enhance the effectiveness of site preparation. SS-Proje documents each step, identifies potential issues in advance, and prepares intervention plans using a project checklist. This systematic approach ensures smooth and timely assembly.

Communication and team coordination also play a critical role in site preparation. SS-Proje ensures effective information flow between the on-site team and office, guarantees harmonized progress at each step, and provides rapid solutions to unexpected situations. These methods ensure high-quality and efficient project execution.

Pre-assembly site preparation enables successful project completion through proper planning, equipment checks, and process management. SS-Proje guarantees safe and efficient results in projects with comprehensive site preparation steps.

Common Issues During Assembly and Preventive Strategies

The assembly process is a critical phase for timely and smooth project completion. However, common issues during this stage can disrupt workflow and increase costs. SS-Proje identifies common issues during assembly in advance and applies effective preventive strategies to ensure smooth project progress.

One of the most common issues is insufficient prior evaluation of site conditions. Incomplete checks of factors such as ground condition, electrical, and water infrastructure can cause assembly delays. SS-Proje inspects all critical elements in advance and eliminates potential risks through site preparation checks.

Equipment and material shortages or incorrect usage are another frequent problem during assembly. SS-Proje ensures all tools and equipment are complete and operational and guarantees materials are available on-site through assembly equipment checks. This approach supports uninterrupted workflow.

Lack of planning and documentation can also reduce process efficiency. SS-Proje records each step in detail using a project checklist, anticipates potential issues, and prepares solution strategies. This ensures the assembly process progresses in a planned and manageable manner.

Poor communication and insufficient team coordination can lead to unexpected delays. SS-Proje ensures effective information flow between the site team and office, guaranteeing coordinated progress at each step. This approach enables high-quality and efficient project execution.

Preventing issues during assembly is possible through proper planning, equipment checks, process management, and effective communication. SS-Proje guarantees safe and efficient outcomes in projects with comprehensive assembly preventive strategies.

Ways to Increase Efficiency in Assembly Through Site Preparation

Increasing efficiency during assembly depends on proper site preparation for timely and smooth project completion. SS-Proje optimizes assembly processes through site preparation, accelerating workflow and improving quality. Every detail considered during preparation directly affects project efficiency.

First, a detailed assessment of site conditions is necessary. Factors such as ground condition, electrical and water infrastructure, and material storage areas ensure smooth assembly. SS-Proje meticulously inspects all these elements and makes necessary adjustments through site checks, enabling uninterrupted workflow.

Equipment and material management is another important factor that increases assembly efficiency. SS-Proje ensures all tools and equipment are complete and operational and guarantees materials are available on-site through assembly equipment checks. This prevents delays and errors during assembly.

Planning and process management further enhance site preparation effectiveness. SS-Proje documents each step, anticipates potential disruptions, and prepares solution plans using a project checklist. This systematic approach supports organized and efficient assembly.

Communication and team coordination play a critical role in site preparation. SS-Proje ensures effective information flow between the site team and office, guaranteeing harmonized progress at each step. This maximizes efficiency during assembly and optimizes project completion time.

Site preparation is the key to increasing assembly efficiency through proper planning, equipment checks, process management, and effective communication. SS-Proje guarantees smooth and efficient project completion with comprehensive site preparation steps.

Pre-Assembly Planning: Effective Tactics to Prevent Project Delays

Pre-assembly planning is a critical step to ensure timely and smooth project completion. SS-Proje prevents project delays through meticulous analysis and coordination in the pre-assembly planning process. Proper planning, site preparation, equipment and material management ensure efficient workflow.

First, a detailed assessment of site conditions is necessary. Factors such as ground condition, electrical and water infrastructure, and material storage areas must be pre-checked to ensure smooth assembly. SS-Proje inspects these elements thoroughly and makes necessary adjustments through site checks.

Equipment and material management is an indispensable part of pre-assembly planning. SS-Proje verifies that all tools and equipment are complete and operational and guarantees materials are ready on-site through assembly equipment checks. This prevents potential disruptions and delays.

Planning and documentation are other critical steps that enhance pre-assembly process efficiency. SS-Proje records each step using a project checklist, anticipates potential risks, and prepares solution plans. This systematic approach ensures organized and efficient assembly progress.

Communication and team coordination play a vital role in preventing project delays. SS-Proje ensures effective information flow between the site team and office, guaranteeing harmonized progress at each step. Thus, pre-assembly planning ensures projects are completed on time and without issues.

Pre-assembly planning prevents project delays through proper site checks, equipment and material management, process monitoring, and effective communication. SS-Proje guarantees smooth and efficient project progress with comprehensive pre-assembly tactics.