Mechanical Powder Transfer

- Blog

- Mechanical Powder Transfer

Mechanical Powder Transfer

Table of Contents

- What Is Mechanical Dust Transfer?

- How Does Mechanical Dust Transfer Work?

- What Are the Differences Between Mechanical and Vacuum Dust Transfer Systems?

- In Which Industries Is Mechanical Dust Transfer Used?

- How to Increase Efficiency in Mechanical Dust Transfer Systems?

- What Advantages Do Screw Conveyors Offer for Dust Transfer?

- How Are Bucket Elevators Used in Mechanical Dust Transfer?

- Achieve Production Quality with SS Proje’s Mechanical Dust Transfer Solutions

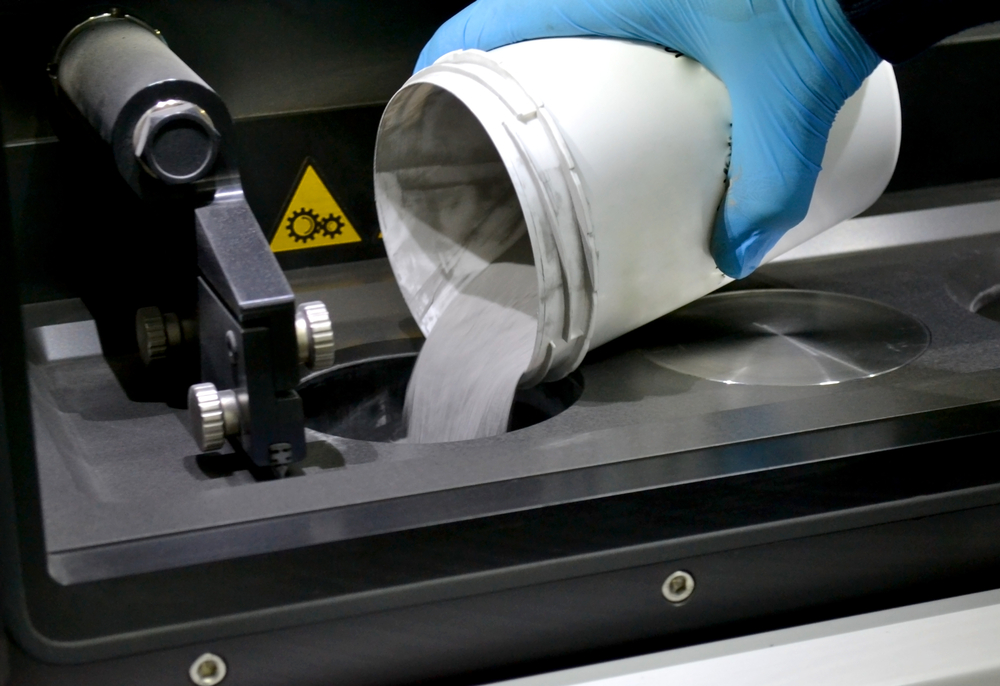

What Is Mechanical Dust Transfer?

Mechanical dust transfer is the process of transporting dust or granular materials from one point to another using physical moving parts. These systems operate with equipment such as screw conveyors, belt conveyors, bucket elevators, and chain conveyors. The primary goal is to transfer the material continuously and controllably with minimal loss to the desired location.

Mechanical systems are particularly preferred for transporting high-volume and heavy dusts. Their robust structure provides an advantage in challenging production environments compared to vacuum systems. Additionally, the transfer process can be adjusted based on the material type, offering a flexible and customizable solution.

These systems are commonly used in industries such as cement, mining, construction chemicals, energy production, and agriculture. Factors like dust density, abrasiveness, and flowability are critical in system design.

How Does Mechanical Dust Transfer Work?

Mechanical dust transfer is a system that transports dust or granular materials from one point to another using physical transport equipment. These systems utilize mechanical tools such as screw conveyors, bucket elevators, chain conveyors, or vibratory conveyors. The material is moved through the system via the rotating or pushing motion of these components.

One of the most common systems, screw conveyors, transport dust horizontally or at an incline using a rotating screw shaft. Bucket elevators, on the other hand, are used for vertical transport needs, lifting materials upward with buckets. These systems are typically powered by motors, and their transport speeds can be adjusted to meet production requirements.

Mechanical systems are designed specifically for the capacity and material type. The particle size, density, and abrasiveness of the dust are considered when selecting the appropriate material and structure.

What Are the Differences Between Mechanical and Vacuum Dust Transfer Systems?

Mechanical and vacuum dust transfer systems are two distinct methods for transporting dust materials. These systems differ based on their application areas, material characteristics, and production conditions.

Mechanical systems operate with moving parts such as screw conveyors, bucket elevators, or chain conveyors. This method is particularly advantageous for transporting high-capacity and heavy dusts. Their robust structures make them preferred in demanding industrial environments. However, due to moving parts, they require more maintenance and have a higher risk of dust leakage.

Vacuum systems, on the other hand, are closed systems that use negative pressure to draw dust through pipes. These systems are commonly used in hygiene-critical industries (food, pharmaceuticals, chemicals). Vacuum transfer offers advantages like dust-free operation, operator safety, and easy cleaning but may be more limited in high-capacity applications compared to mechanical systems.

In Which Industries Is Mechanical Dust Transfer Used?

Mechanical dust transfer is widely used in numerous industrial sectors due to its high-capacity and durable structure. These systems ensure the safe, continuous, and controlled transport of dust or granular raw materials.

The cement and construction industry is one of the primary sectors utilizing mechanical transfer systems. Abrasive materials like cement, lime, and gypsum are transported seamlessly using screw conveyors or bucket elevators.

In the mining and metallurgy sectors, durable mechanical systems are preferred for transporting heavy and coarse dusts.

In the energy sector, these systems are used for transferring coal dust, ash, and similar byproducts.

In the food and agriculture industries, mechanical systems are used for horizontal or vertical transport of products like flour, feed, and grains.

In the chemical industry, they provide a reliable solution for transferring pigments, fillers, and mineral-based dusts.

SS Proje develops long-lasting and efficient mechanical dust transfer solutions tailored to the material characteristics and production needs of each sector.

How to Increase Efficiency in Mechanical Dust Transfer Systems?

Increasing efficiency in mechanical dust transfer systems is critical for ensuring production continuity and reducing maintenance costs. Proper system design, regular maintenance, and automation integration are key elements for efficiency improvement.

First, the equipment must be selected based on the dust’s properties (density, moisture, particle size, abrasiveness). For instance, heavy or sticky materials require more durable screw or chain conveyors to prevent system blockages or frequent breakdowns.

To reduce energy consumption, motor power and transport speed should be accurately calculated. Overworking systems lead to both energy waste and equipment wear. Integrating the system with automation allows real-time monitoring and optimization of material flow.

Regular maintenance and critical component checks prevent unexpected downtimes. Using sealed structures to ensure dust containment enhances environmental cleanliness and minimizes product loss.

What Advantages Do Screw Conveyors Offer for Dust Transfer?

Screw conveyors are widely used mechanical transport systems for dust and granular materials. Their rotating screw structure enables efficient and continuous transfer of dust horizontally, at an incline, or vertically. These systems are favored across industries for their simple design and low operating costs.

One of their key advantages is their closed system design, which prevents dust leakage and keeps the environment clean. Additionally, their compact design allows easy installation in confined spaces and seamless integration into existing lines. Screw conveyors provide consistent and controlled flow, ensuring high precision in weighing and dosing operations.

Maintenance and cleaning are straightforward, and with fewer moving parts, the risk of breakdowns is low. SS Proje enhances transport efficiency with screw conveyor solutions tailored to your production line, offering a long-lasting and safe system that ensures continuity and minimizes costs.

How Are Bucket Elevators Used in Mechanical Dust Transfer?

Bucket elevators are mechanical transport systems designed to move dust and granular materials vertically or at an incline. These systems operate using buckets fixed to a belt or chain. The material is picked up from the entry point at the bottom, transported upward, and discharged controllably at the top.

Bucket elevators are particularly preferred in high-capacity and vertical transport facilities. They are widely used in industries like cement, flour, feed, chemicals, and mining for the safe transport of dusty products. Their enclosed structure ensures dust containment, enhancing both environmental cleanliness and operator safety.

These systems offer high transport capacity even in confined spaces. They are also energy-efficient, as gravity assists in material transport, achieving high performance with low energy consumption.

Achieve Production Quality with SS Proje’s Mechanical Dust Transfer Solutions

Success in industrial production depends not only on raw material quality but also on the accurate and efficient transport of those materials. SS Proje offers high quality, continuity, and durability with mechanical dust transfer solutions. Systems designed with equipment like screw conveyors, bucket elevators, and chain conveyors are ideal for high-capacity and challenging production environments.

SS Proje develops customized engineering solutions tailored to each industry’s needs. Factors such as dust density, moisture content, abrasiveness, and transport distance are considered to determine the optimal transport system. This minimizes material loss, energy consumption, and maintenance costs.

When integrated with automation, mechanical systems provide high production speed and traceability. With SS Proje’s expertise, your facility gains not only efficiency but also sustainability. Choose reliable mechanical dust transfer systems to achieve production quality and experience the difference.