Rapid Assembly Solutions: Implementation Guide for Emergency Capacity Increase

- Blog

- Rapid Assembly Solutions: Implementation Guide for Emergency Capacity Increase

Rapid Assembly Solutions: Implementation Guide for Emergency Capacity Increase

Contents

- Rapid Assembly Solutions: Step-by-Step Implementation Guide for Emergency Capacity Increase

- Practical Solutions to Apply in Assembly Processes to Quickly Increase Production Capacity

- 7 Ways to Be Prepared for Sudden Demand Surges with Rapid Assembly

- Speed and Efficiency in Assembly Processes: How KPIs Are Measured During Emergency Capacity Increase

- Rapid Assembly vs. Traditional Assembly: Which Is More Effective in Emergency Capacity Increase?

- Rapid Assembly Trends and Emergency Capacity Solutions in Production for 2025

Rapid Assembly Solutions: Step-by-Step Implementation Guide for Emergency Capacity Increase

Sudden demand surges in industrial production can create serious capacity management challenges for businesses. SS Proje enables emergency capacity increases with rapid assembly solutions and minimizes operational efficiency losses on production lines. This guide details the steps to be taken in the rapid assembly process and key points to consider.

The first step is a current state analysis and bottleneck identification of the existing production line. SS Proje identifies critical points in the processes and determines where rapid intervention is needed. This analysis ensures the most efficient use of resources and allows assembly times to be shortened.

The second step is implementing modular assembly techniques. Modular systems allow teams to work in parallel and minimize disruptions on the production line. SS Proje optimizes the assembly of each module to implement emergency capacity increases quickly and safely.

The third step emphasizes team coordination and workflow management. SS Proje ensures clear communication and task distribution among teams throughout the process, reducing errors and increasing production capacity.

The fourth step involves setting up performance measurement and monitoring systems. KPI tracking and real-time data analysis allow delays and inefficiencies in the assembly process to be quickly identified and corrected. This method maximizes the impact of emergency capacity increases.

The final step is the continuous improvement of the process. With SS Proje's rapid assembly solutions, processes are standardized, repeatable, and contribute to overall efficiency gains across the business.

Practical Solutions to Apply in Assembly Processes to Quickly Increase Production Capacity

Sudden demand increases in production facilities put pressure on production capacity. SS Proje enables rapid intervention in such situations through practical solutions in assembly processes. This article outlines step-by-step methods to increase production capacity.

The first step is a detailed process analysis of the current production line. SS Proje identifies bottlenecks in the production flow and determines which points need acceleration. This analysis minimizes unnecessary waiting and delays.

Secondly, modular assembly systems should be implemented. Modular structures allow assembly teams to work in parallel and reduce assembly time. SS Proje provides optimized assembly steps for each module to achieve rapid capacity increases on the production line.

The third step focuses on workforce coordination and task distribution. SS Proje ensures clear communication and responsibilities among teams, reducing errors and improving production efficiency.

The fourth step involves performance monitoring and KPI measurement. Data collected throughout the assembly process quickly identifies delays, allowing corrective actions. SS Proje ensures continuity and speed in production this way.

Finally, continuous process improvement is crucial. The practical assembly solutions offered by SS Proje standardize and make production processes repeatable, achieving long-term efficiency gains.

7 Ways to Be Prepared for Sudden Demand Surges with Rapid Assembly

Sudden demand surges can quickly strain production facility capacity. SS Proje offers effective solutions for such scenarios through rapid assembly methods. Here are seven ways to maintain uninterrupted performance in production:

First, conduct a process analysis of the production line. SS Proje identifies bottlenecks and delay points to accelerate the assembly process.

Second, use modular assembly systems. These systems allow teams to work on different modules simultaneously, rapidly increasing production capacity.

Third, optimize workforce and task distribution. SS Proje reduces errors and improves efficiency through team coordination and clear responsibility allocation.

Fourth, implement KPI tracking and performance measurement. This ensures that any issues during assembly are quickly identified and resolved.

Fifth, optimize material and equipment management. SS Proje’s practical assembly solutions speed up material flow and prevent unnecessary waiting.

Sixth, standardize production processes. Standard assembly protocols ensure high efficiency each time and reduce adaptation time for teams.

Seventh, provide continuous training and employee skill development. This enables fast and error-free assembly during sudden demand surges.

Speed and Efficiency in Assembly Processes: How KPIs Are Measured During Emergency Capacity Increase

Emergency capacity increases make speed and efficiency critical in production processes. SS Proje focuses on enhancing operational performance through effective KPI measurement in assembly processes. KPIs are essential tools for evaluating assembly line efficiency, workforce productivity, and process optimization.

First, the production speed KPI should be monitored. This indicator measures how many products are completed within a specific time and is critical for understanding capacity under emergency demand.

Second, error rate should be tracked. SS Proje records errors during assembly to ensure quality and guide process improvements.

The third KPI is workforce efficiency. Task allocation and time management directly affect efficiency; SS Proje provides detailed analyses to optimize performance.

Fourth, material flow and inventory management KPIs are important. Delays in material supply can extend assembly times; SS Proje minimizes this risk with process adjustments.

The fifth KPI is total cycle time, measuring the time from a product entering the assembly line to completion—a critical indicator during emergency demand periods.

Sixth, comprehensive performance reporting should regularly track and analyze all KPIs. SS Proje ensures rapid implementation of efficiency-enhancing measures in assembly processes.

Finally, a continuous improvement approach optimizes assembly processes based on KPI data, achieving sustainable performance during emergency capacity increases.

Rapid Assembly vs. Traditional Assembly: Which Is More Effective in Emergency Capacity Increase?

Emergency capacity increases directly impact the efficiency of assembly processes. SS Proje compares rapid assembly and traditional assembly methods to analyze which approach is more efficient during urgent demand periods.

Rapid assembly minimizes production time using pre-planned modular components and standardized equipment. This method quickly scales the production line during emergency demand and increases production capacity. SS Proje maximizes efficiency by monitoring every stage of the process with KPI measurements.

On the other hand, traditional assembly is more flexible but time-consuming. Each product or component is manually assembled, and the process requires high labor intensity. This approach limits rapid response to emergency capacity increases and may raise the error rate.

SS Proje highlights the advantages of rapid assembly while noting that traditional assembly is suitable for complex and customized products. Additionally, rapid assembly ensures controlled and predictable processes regarding material flow and inventory management.

With rapid assembly, cycle times are short, workforce efficiency is high, and quality standards are maintained. In traditional assembly, adaptation time is longer, and costs and labor requirements are higher. SS Proje compares both methods using KPI data to determine the best strategy for production management.

In conclusion, rapid assembly methods stand out as the preferred choice for emergency capacity increases due to their flexible and efficient structure.

Rapid Assembly Trends and Emergency Capacity Solutions in Production for 2025

The year 2025 brings significant innovations in rapid assembly solutions. SS Proje examines strategies that prepare production processes for emergency capacity increases and highlights the contribution of modern assembly methods to operational efficiency.

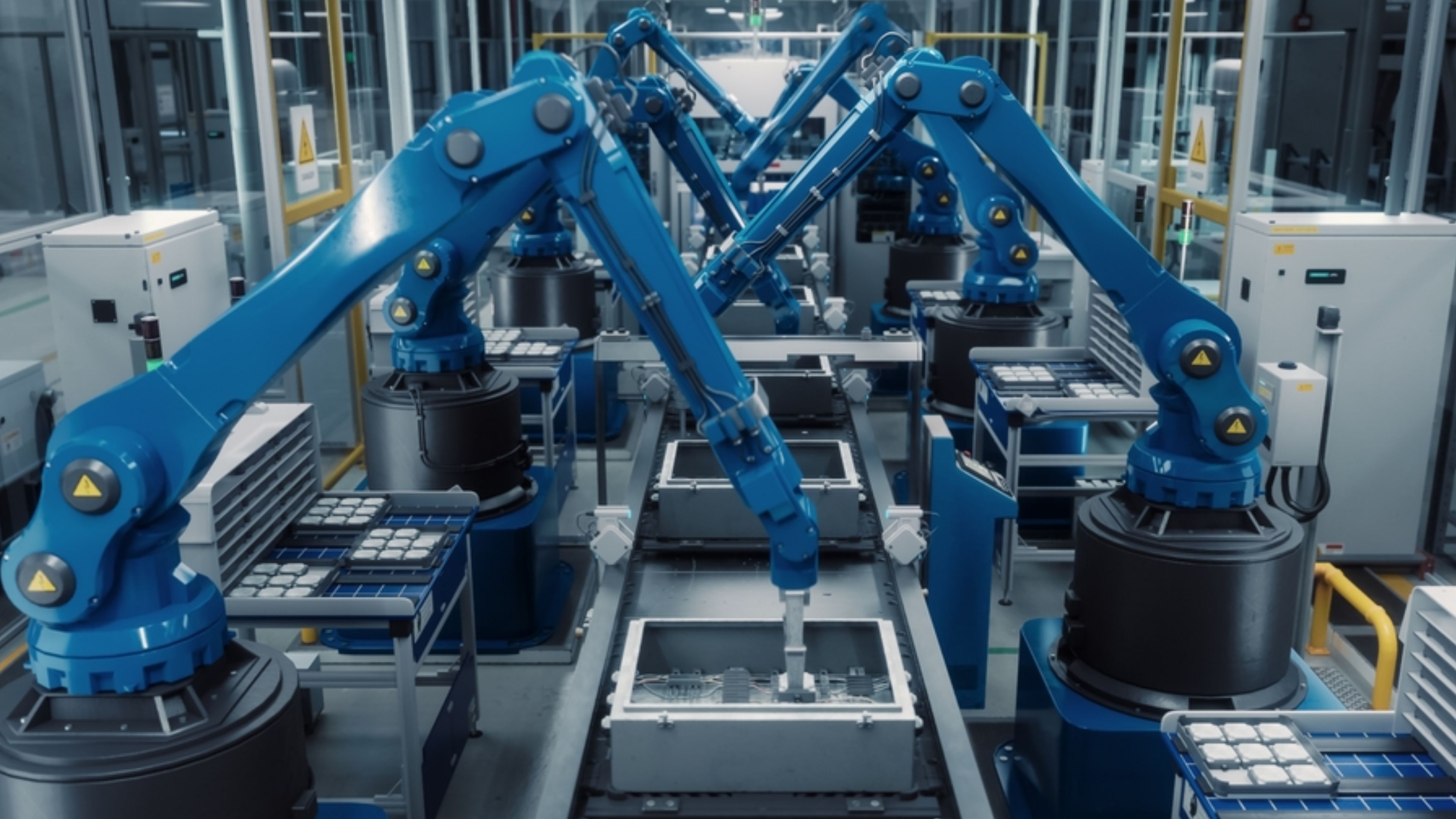

Modular assembly systems are one of the most popular trends in 2025. These systems allow rapid reconfiguration of production lines and instant capacity increases. SS Proje emphasizes that applying modular systems can significantly shorten production times and save labor.

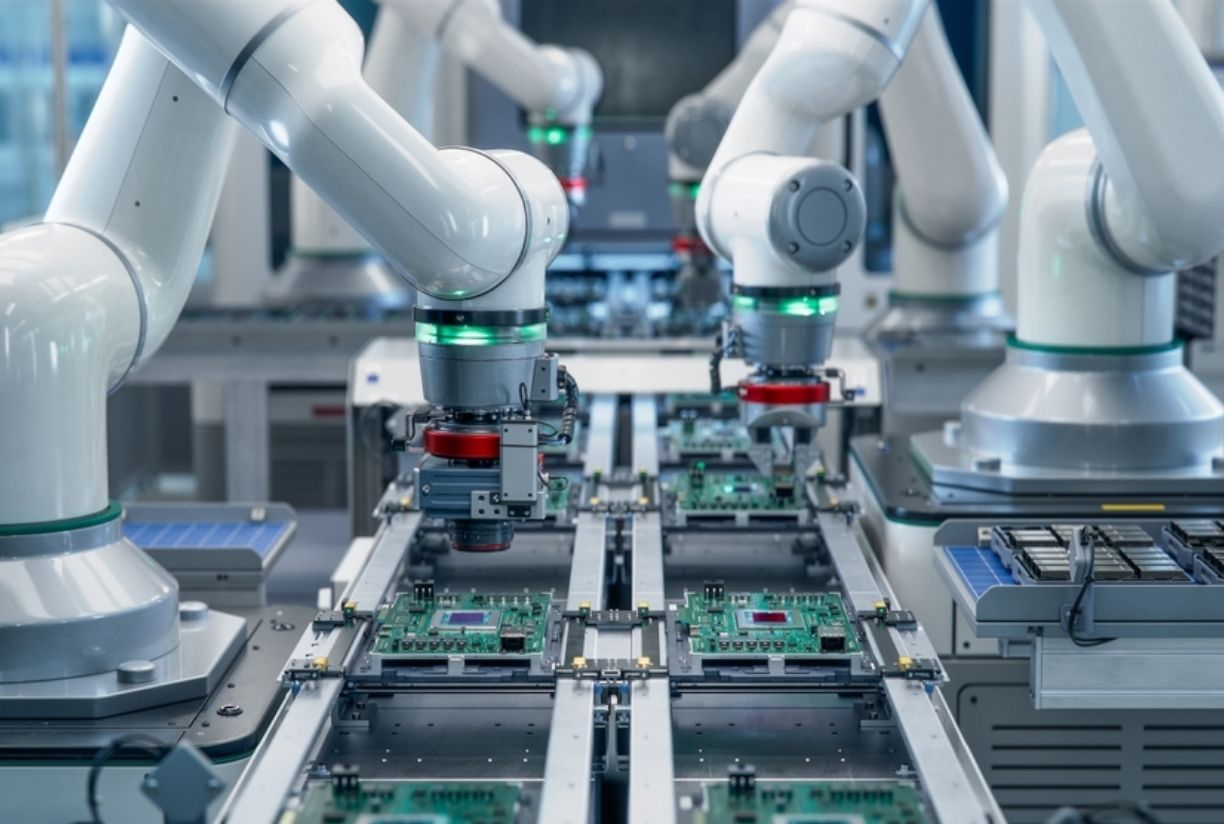

Automation and robotic integration also play a critical role in rapid assembly processes. They reduce human error during emergency demand surges and increase production efficiency. SS Proje's KPI data shows that assembly times can be improved by up to 30% with automation.

Another trend is process optimization and data analytics for monitoring production performance. SS Proje uses sensors and software solutions to detect bottlenecks and continuously monitor speed and quality metrics on the assembly line.

In 2025, rapid assembly solutions not only shorten production time but also provide flexible capacity management and cost savings. SS Proje minimizes uncertainties in production with practical solutions and KPI-focused monitoring systems suitable for emergency capacity demands.

The strategies implemented by SS Proje serve as an important reference for enhancing assembly process performance and ensuring sustainable efficiency in production.