Safe Surface Treatment with Certified Stainless Steel Passivation

- Blog

- Safe Surface Treatment with Certified Stainless Steel Passivation

Safe Surface Treatment with Certified Stainless Steel Passivation

Table of Contents

- The Impact Of Certified Stainless Steel Passivation On Equipment Lifetime And Regulatory Compliance

- A Cost Benefit Comparison Of Passivation And Standard Coating For Long Term Facility Efficiency

- A Guide To Safe Surface Treatment With Certified Passivation For Minimal Downtime

- Why Stainless Steel Equipment Requires Professional Passivation For Sustainable Performance

- How Certified Passivation Meets International Quality Standards

- The Role Of Expert Passivation In Increasing Return On Investment For Stainless Steel Assets

- A Technical Guide To Stainless Steel Passivation For Corrosion Resistance And Lower Maintenance Costs

The Impact Of Certified Stainless Steel Passivation On Equipment Lifetime And Regulatory Compliance

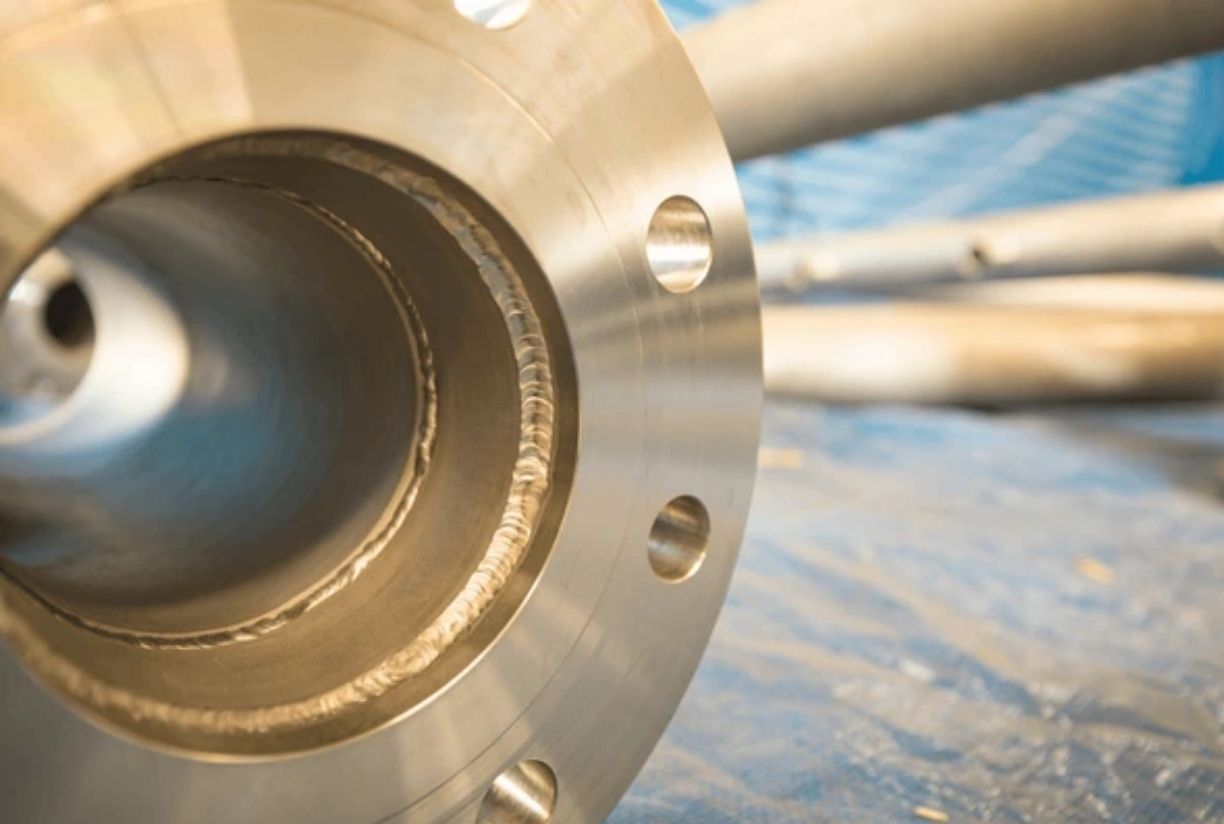

Certified stainless steel passivation is a critical safe surface treatment that chemically enhances the innate corrosion resistance of stainless steel, forming a durable, invisible chromium oxide layer. In demanding industrial environments, even high-grade alloys are susceptible to pitting and crevice corrosion initiated by free iron contamination and welding scale. This degradation directly threatens asset integrity, product purity, and operational continuity. Implementing a certified passivation protocol is therefore a fundamental engineering practice to proactively extend equipment life and uphold the stringent requirements of international quality standards compliance.

The technical process involves meticulous cleaning to remove all contaminants, followed by controlled immersion in an acid bath—typically nitric or citric acid—to dissolve free iron particles and promote the formation of the protective passive layer. The "certified" aspect is paramount, referring to adherence to strict protocols like ASTM A967 or AMS 2700, which ensure repeatable results and provide verifiable documentation for audits. This level of rigor, integral to a comprehensive process optimization consultancy, guarantees maximum corrosion resistance for industrial equipment such as tanks, mixers, and filter housings. Expertise from specialized firms like SS Proje engineering ensures this process is executed with precision, safeguarding critical assets.

The operational and financial benefits are substantial. By preventing corrosion, passivation eliminates a primary cause of premature equipment failure, dramatically reducing maintenance costs and unplanned downtime. For facilities in regulated sectors like pharmaceuticals, food and beverage, and chemicals, this treatment is non-negotiable for validating clean-in-place (CIP) systems and ensuring product safety. This preventative measure is a cornerstone of sustainable facility solutions, as it minimizes waste from part replacement and maintains consistent, efficient process performance over decades rather than years.

Ultimately, investing in certified passivation transforms stainless steel from a vulnerable material into a highly resilient one. It is a relatively low-cost intervention that delivers an exceptional return by protecting high-value capital equipment from degradation. This proactive approach to asset management is essential for any facility committed to long-term reliability, regulatory adherence, and operational excellence, ensuring that equipment not only survives but thrives in harsh industrial conditions.

A Cost Benefit Comparison Of Passivation And Standard Coating For Long Term Facility Efficiency

When selecting a surface protection strategy for industrial assets, the choice between certified stainless steel passivation and standard organic or epoxy coatings demands a rigorous cost-benefit analysis focused on lifecycle performance. While coatings apply an external layer that can chip, peel, or degrade over time, passivation is an electrochemical process that enhances the metal's inherent properties. This fundamental difference makes passivation the superior choice for applications demanding hygiene, durability, and long-term value, directly supporting goals for sustainable facility solutions and robust corrosion resistance for industrial equipment.

The initial application cost of a standard coating may appear lower, but its lifecycle expenses are often significantly higher. Coatings require extensive surface preparation, are susceptible to damage during operation or cleaning, and necessitate frequent reapplication, leading to recurring costs and production interruptions. In contrast, safe surface treatment via passivation creates a integral oxide layer that cannot delaminate and actually self-repairs in the presence of oxygen. This inherent durability is a key factor to extend equipment life and is a central consideration in any thorough process optimization consultancy.

For regulated industries, the compliance advantages of passivation are decisive. Coatings can harbor microorganisms, release particles, and complicate cleaning validation, posing significant risks to product quality and international quality standards compliance. Passivated surfaces, being monolithic and ultra-smooth, are inherently cleanable and sterilizable, making them essential for pharmaceutical, food, and biotechnology applications. Engineering partners like SS Proje engineering prioritize passivation for these critical systems to ensure unwavering reliability and audit-ready documentation.

The long-term financial and operational benefits firmly establish passivation as the high-return option. It eliminates the maintenance cycles and downtime associated with coating repair, providing decades of reliable service with minimal intervention. By choosing this advanced safe surface treatment, facilities make a strategic investment in risk reduction, operational continuity, and total cost of ownership, securing a competitive edge through superior engineering and proven protection for high-value assets.

A Guide To Safe Surface Treatment With Certified Passivation For Minimal Downtime

A disciplined five-step protocol is essential for executing certified stainless steel passivation that delivers maximum protection with minimal disruption to production schedules. The process begins with a thorough alkaline cleaning to remove all organic residues, oils, and greases that could interfere with the chemical treatment. This is followed by a precise rinse with high-purity water to eliminate any cleaning agent traces, ensuring a contaminant-free surface. This meticulous preparation is the foundation of a truly effective safe surface treatment and is critical for achieving the desired corrosion resistance for industrial equipment.

The core chemical stage involves controlled immersion in a passivation bath, typically using nitric or citric acid, which dissolves free iron particles from the surface without etching the base metal. The concentration, temperature, and immersion time are strictly controlled according to relevant standards like ASTM A967 to ensure consistency and certification. A subsequent neutralization and final rinse step removes all chemical residues, preparing the surface for the passive layer to form. This precision execution, a specialty of firms like SS Proje engineering, is integral to a comprehensive process optimization consultancy aimed at long-term asset protection.

The final step is drying and documentation, where the component is dried completely to prevent water spotting and initiate the formation of the protective chromium oxide layer. A certificate of compliance is generated, providing auditable proof that the process meets international quality standards compliance. This documented process not only validates the treatment for regulatory purposes but also serves as a key record for lifecycle asset management. When planned effectively, this entire sequence can be completed during a planned maintenance window, minimizing impact on operations.

Adhering to this structured five-step guide transforms passivation from a simple chemical process into a strategic reliability initiative. It ensures that critical assets like reactors, pipelines, and tanks receive uniform, verifiable protection that will extend equipment life for decades. This methodical approach is a cornerstone of sustainable facility solutions, as it maximizes asset utilization, reduces lifecycle costs, and builds a foundation of operational certainty that is essential for competitive industrial performance.

Why Stainless Steel Equipment Requires Professional Passivation For Sustainable Performance

Investing in professional certified stainless steel passivation is a non-negotiable strategy for asset managers targeting true sustainable performance. Stainless steel's corrosion resistance is not inherent but dependent on a continuous, uncontaminated chromium oxide layer that can be compromised during fabrication, welding, and handling. Without this vital safe surface treatment, even high-grade alloys are vulnerable to pitting, crevice corrosion, and surface contamination that degrade performance and shorten service life. This makes professional passivation a fundamental pillar of any long-term process optimization consultancy focused on lifecycle asset management.

The first critical reason is contamination control. Fabrication processes embed microscopic iron particles into the stainless steel surface, which act as initiation sites for rust and corrosion. Professional passivation systematically removes these contaminants, restoring the material's innate resistance and ensuring product purity in sensitive applications. Secondly, the treatment provides unmatched corrosion resistance for industrial equipment operating in harsh chemical or high-humidity environments, directly helping to extend equipment life by decades. Specialized engineering providers like SS Proje engineering deliver this service with the precision required for critical assets.

For regulated industries, the compliance imperative is paramount. Professional passivation provides verifiable documentation proving adherence to international quality standards compliance such as ASTM A967 and AMS 2700, which is essential for audit success in pharmaceutical, food, and chemical sectors. Furthermore, a properly passivated surface minimizes friction and biofilm adhesion, reducing energy consumption for pumping and cleaning while maintaining hygienic conditions. This contributes directly to operational efficiency and environmental goals.

Ultimately, viewing passivation as a discretionary cost is a significant strategic error. It is a essential capital preservation technique that prevents exponentially higher expenses from premature asset replacement, product contamination, and regulatory non-compliance. By integrating this proven safe surface treatment into your maintenance philosophy, you secure not only the mechanical integrity of your equipment but also the operational reliability and regulatory standing of your entire facility, making it a cornerstone of modern industrial sustainability.

How Certified Passivation Meets International Quality Standards

For facilities operating under strict regulatory oversight, verifying surface treatment compliance is a critical operational requirement, not an optional audit exercise. Many surface treatments, including improper passivation methods or non-certified coatings, fail to meet the rigorous validation criteria demanded by global standards. Certified stainless steel passivation distinguishes itself by adhering to codified protocols like ASTM A967, AMS 2700, and ISO 16048, which provide a verifiable framework for achieving and demonstrating international quality standards compliance. This certification is the definitive proof that a safe surface treatment has been executed correctly.

The certification process begins with meticulous documentation of every parameter, including chemical concentrations, bath temperatures, immersion times, and rinse water quality. Post-treatment verification tests, such as the copper sulfate test for free iron removal or salt spray testing for corrosion resistance, provide objective data confirming the treatment's efficacy. This level of traceability is essential for auditors and is a core deliverable of a professional process optimization consultancy. Engineering specialists like SS Proje engineering embed this documentation into their project lifecycle, ensuring full transparency and accountability.

Beyond audit readiness, compliant passivation delivers direct operational advantages. The superior corrosion resistance for industrial equipment achieved through certified processes directly functions to extend equipment life and prevent contamination in sensitive processes. In industries like pharmaceuticals and food production, where surface cleanliness is synonymous with product safety, this compliance is non-negotiable. It ensures that equipment not only performs reliably but also protects brand reputation and consumer safety, aligning with the highest principles of sustainable facility solutions.

Ultimately, choosing certified passivation is a strategic decision that mitigates regulatory risk while maximizing asset performance. It transforms a surface treatment from a potential liability into a documented asset, providing peace of mind and operational certainty. In an era of increasing regulatory scrutiny, this approach is indispensable for any facility committed to excellence, safety, and long-term market access, ensuring that every component meets the highest global benchmarks for quality and reliability.

The Role Of Expert Passivation In Increasing Return On Investment For Stainless Steel Assets

Maximizing the return on investment for high-value stainless steel assets requires a strategic approach that views equipment not as a purchase but as a long-term capital investment. While stainless steel is chosen for its durability, its performance and longevity are heavily dependent on the integrity of its protective oxide layer. Certified stainless steel passivation is the most cost-effective intervention to ensure this integrity, directly contributing to enhanced process optimization by eliminating corrosion-related inefficiencies and disruptions. This proactive safe surface treatment is a cornerstone of a sound asset management strategy.

The financial return is realized through multiple channels. The most significant is the drastic extension of the asset's productive life; professional passivation can add decades of service by preventing the pitting and crevice corrosion that lead to failure. This directly defers massive capital expenditure on replacements. Furthermore, a passivated surface offers superior corrosion resistance for industrial equipment, which minimizes maintenance frequency, reduces spare part costs, and eliminates the production downtime associated with repairs. This holistic benefit is a key focus of any advanced process optimization consultancy.

Expert execution is critical to achieving these returns. Proper passivation by specialists like SS Proje engineering involves rigorous cleaning, precise chemical treatment, and thorough verification to ensure the passive layer is fully formed and durable. This expertise guarantees that the treatment will consistently extend equipment life and meet the stringent requirements for international quality standards compliance, which is essential for facilities in regulated industries to avoid costly audit failures and production stoppages.

When evaluated on a lifecycle cost basis, the ROI of expert passivation is exceptional. The initial investment is fractional compared to the avoided costs of premature asset replacement, unplanned downtime, and non-compliance penalties. This makes it a fundamental practice for achieving sustainable facility solutions, as it maximizes resource utilization and ensures that stainless steel assets deliver their full potential for reliability, efficiency, and value over their entire operational lifespan.

A Technical Guide To Stainless Steel Passivation For Corrosion Resistance And Lower Maintenance Costs

Stainless steel's renowned durability is contingent upon the integrity of its passive layer, a thin chromium oxide film that protects the base metal from oxidation. However, fabrication processes like welding, machining, and grinding contaminate the surface with free iron particles, compromising this natural defense and creating sites for corrosive attack. Certified stainless steel passivation is the engineered solution to this vulnerability, a chemical safe surface treatment that restores and enhances the material's innate corrosion resistance for industrial equipment. This process is fundamental to achieving long-term reliability and significantly reducing lifecycle maintenance costs.

The technical procedure is a sequence of controlled steps. It begins with an alkaline clean to remove all organic soils, followed by a vigorous water rinse. The critical phase is immersion in a passivating acid bath—nitric or citric acid—which selectively dissolves the embedded free iron without significantly attacking the chromium-rich base metal. Parameters such as concentration, temperature, and contact time are strictly controlled according to standards like ASTM A967 to ensure a consistent, high-quality result. This precision, a hallmark of providers like SS Proje engineering, is essential for a successful outcome that will reliably extend equipment life.

The benefits of this meticulous approach are direct and substantial. By eliminating the initiation points for corrosion, passivation prevents pitting and rust, which are primary causes of equipment failure and costly repairs. This leads to a dramatic reduction in maintenance frequency and spare part consumption. For process engineers, this translates into predictable operational budgets and minimized unplanned downtime. This strategic advantage is a key component of a comprehensive process optimization consultancy, focusing on total cost of ownership rather than isolated expenses.

Ultimately, integrating certified passivation into your asset management protocol is a powerful strategy for sustainable facility solutions. It ensures compliance with international quality standards, protects your capital investment, and delivers a high return through avoided downtime and replacement costs. This technical guide underscores that passivation is not a minor finishing step but a critical engineering process that unlocks the full performance potential of stainless steel, ensuring it delivers decades of reliable, cost-effective service in the most demanding industrial environments.