What is the Manufacturing Process?

- Blog

- What is the Manufacturing Process?

What is the Manufacturing Process?

Table of Contents

- What is the Production Process and Why is it Important?

- How Does the Production Process Work in Different Sectors?

- What is the Relationship Between the Production Process and Efficiency?

- What Are the Differences Between Modern Production Processes and Traditional Methods?

- Key Points to Consider in Production Process Management

- Examples of Production Processes in Different Sectors

What is the Production Process and Why is it Important?

The production process is a systematic procedure that covers all stages from the concept of a product to its completion. This process includes steps such as design, planning, raw material procurement, production, and quality control. SS Proje successfully implements projects by prioritizing high efficiency and quality in production processes.

The production process enables businesses to reduce costs, improve time management, and increase product quality. Establishing correct strategies during the planning phase ensures efficient use of resources and helps prevent potential issues on the production line. SS Proje provides clients with detailed analyses and optimized solutions at this stage.

Quality control is an essential part of the production process. Ensuring that each product meets established standards is critical for customer satisfaction and brand reliability. SS Proje minimizes defective products through strict quality inspections throughout the production process.

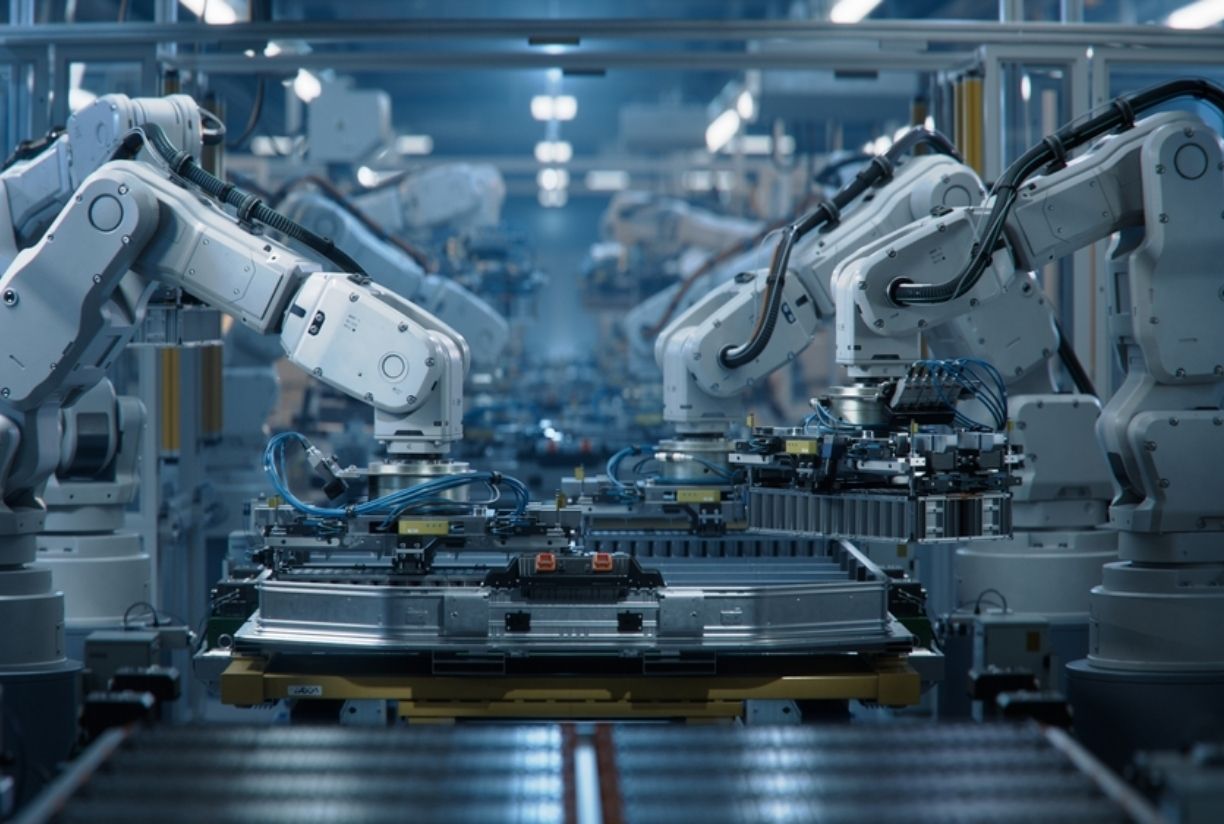

In modern production processes, automation technologies and software play a significant role. These tools reduce labor costs, increase production speed, and minimize human errors. SS Proje optimizes production processes in its projects by using the latest technologies.

When managed correctly, the production process provides a competitive advantage and ensures product quality. SS Proje successfully manages this process with its experienced team and expert approach.

How Does the Production Process Work in Different Sectors?

The production process can vary significantly across different sectors, as each has unique requirements and standards. For example, in the automotive sector, the production process requires detailed planning from design to assembly lines. SS Proje offers specialized solutions to ensure high efficiency and quality in such projects.

In the food sector, the production process focuses primarily on hygiene and freshness. Strict control mechanisms are applied at every stage from raw material procurement to packaging and distribution. SS Proje optimizes this process to reduce costs while raising quality standards.

In the textile sector, the production process includes design, fabric selection, sewing, and quality control. Fast production and error-free products are critical for market competitiveness. SS Proje organizes production lines efficiently, considering sectoral differences.

In the electronics sector, the production process involves assembling and testing sensitive devices. Technological infrastructure and automation systems are used at every stage. SS Proje manages production processes smoothly using advanced technology in this sector.

The production process in each sector determines product quality, safety, and market success. SS Proje successfully implements projects with optimized solutions tailored to sector-specific requirements.

What is the Relationship Between the Production Process and Efficiency?

The production process and efficiency are two critical elements that directly affect each other. An effective production process minimizes wasted time through proper and planned use of resources. SS Proje prepares optimized production plans considering this relationship in its projects.

A well-planned production process requires the correct combination of labor, materials, and technological infrastructure. To increase efficiency, SS Proje identifies bottlenecks in the process and implements necessary adjustments. This reduces production costs while maintaining quality standards.

Disruptions or poor planning on the production line lead to loss of efficiency. SS Proje offers customized production solutions for each project while considering sectoral differences and manages the production process without interruption.

Production lines integrated with automation systems increase efficiency while minimizing human error. SS Proje balances technology and human resources to achieve optimum production performance.

The relationship between production process and efficiency is directly linked to business planning and process management. SS Proje integrates these two elements to achieve maximum success in its projects.

What Are the Differences Between Modern Production Processes and Traditional Methods?

The differences between modern production processes and traditional methods range from production speed to quality control. SS Proje speeds up and improves efficiency in processes using modern production techniques.

Traditional methods rely mainly on manual operations and heavily depend on labor. This can increase error rates and extend production time. In contrast, modern production processes are supported by automation and digital tools, and SS Proje ensures continuity in production with these systems.

Modern methods also provide advantages in efficiency and resource optimization. Material usage is more controlled, and energy consumption is lower. SS Proje leverages these advantages to minimize costs and improve production quality in its projects.

In traditional methods, quality control is usually manual, which prolongs error detection. In modern production processes, sensors, software, and automatic monitoring systems are used. SS Proje ensures consistency and standards in production through these technologies.

Additionally, modern production processes provide flexibility and scalability. SS Proje can quickly adapt the same processes for different projects and respond rapidly to customer demands.

Key Points to Consider in Production Process Management

Production process management is a critical procedure for maintaining efficiency and quality standards. SS Proje implements effective management methods to run projects smoothly.

First, resource planning and time management are among the most important aspects of production management. Ensuring materials and equipment are available on time keeps production flow uninterrupted. SS Proje plans processes in advance to prevent delays.

Quality control is another fundamental element of production management. Standard operating procedures and automated control systems minimize errors. SS Proje continuously monitors quality during production to maintain high standards.

Communication and coordination play a critical role in production management. Regular information flow among employees and departments ensures smooth execution of processes. SS Proje establishes open communication channels among all team members to minimize disruptions.

Risk management and process optimization should not be overlooked. Taking precautions for potential disruptions improves production performance. SS Proje continuously analyzes production processes, identifies improvement opportunities, and applies them.

Examples of Production Processes in Different Sectors

Production process applications in different sectors are tailored to meet the unique requirements of each industry. In the automotive sector, SS Proje optimizes assembly processes on the production line to improve both quality and efficiency. Steps such as parts procurement, production sequencing, and quality control are critical in this sector.

In the food sector, hygiene and freshness are prioritized. SS Proje manages automated packaging and storage processes to ensure food safety. Temperature control and monitoring of expiration dates directly affect production quality.

In the textile sector, sewing and cutting stages form the foundation of production. SS Proje plans each step on the production line to ensure efficient use of labor and materials. The transition from design to production, quality control, and packaging are carefully managed.

In the electronics sector, circuit board assembly and testing processes are critical points in production. SS Proje supports electronic production processes with automation and precise control systems, ensuring error-free product delivery.

Although production processes differ across sectors, the primary goals remain efficiency, quality, and time management. SS Proje optimizes production processes across all sectors, helping businesses gain a competitive advantage.