Argon Source Utilisation in Manufacturing Industry: Solutions for Increasing Durability

- Blog

- Argon Source Utilisation in Manufacturing Industry: Solutions for Increasing Durability

Argon Source Utilisation in Manufacturing Industry: Solutions for Increasing Durability

Contents

- What is Argon Welding?

- The Role of Argon Source in the Manufacturing Industry

- Advantages of Argon Welding

- Methods to Increase Durability with Argon Welding Technique

- Application Areas of Argon Welding

- Argon Welding Equipment and Selection

- Argon Source Prices and Cost Analysis

- The Future of Argon Welding in the Manufacturing Industry

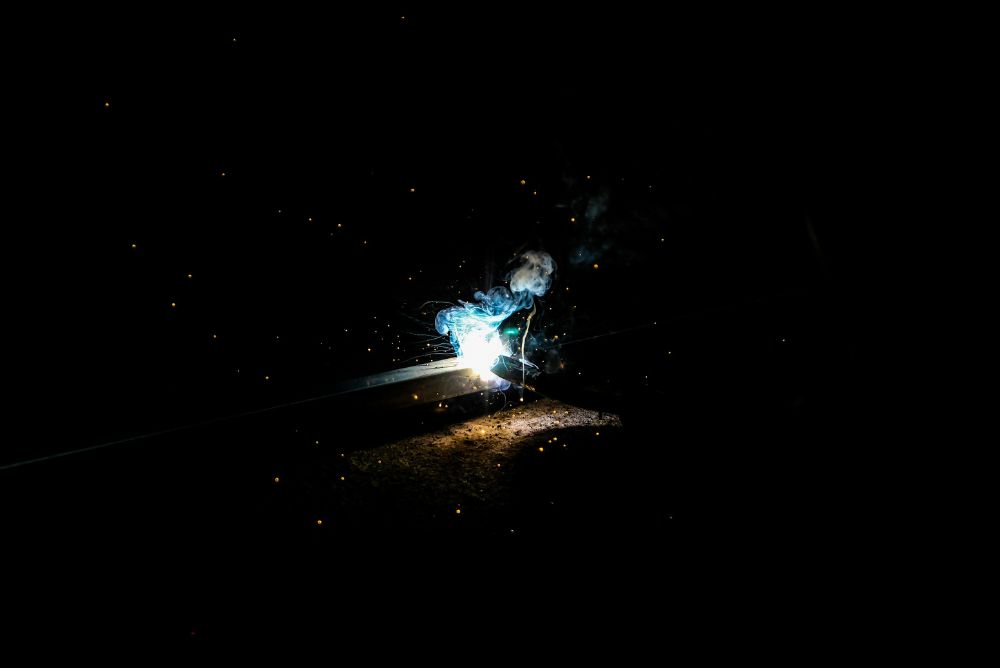

What is Argon Welding?

While SS Project offers durable and reliable production solutions, it adopts an innovative approach that also uses argon welding technique. This technique enables high-quality welds to be obtained, especially in the metalworking and manufacturing industry. argon weldingIt is one of the industrial welding techniques and ensures that the atmosphere around the metal to be welded is protected from harmful components, especially oxygen and nitrogen. during welding argon gas By using it, the weather conditions around the metal to be welded are controlled, which ensures a healthier and safer welding process. Argon gas used in this process works better at high temperatures without damaging the metal surfaces of the weld. a clean source allows it to be done. By preventing oxidation, it is more aesthetic and durable connections allows you to achieve. The role of argon welding in the processing and joining of metal, especially high precision It is evident in industrial applications that require In welding processes of metals prone to oxidation such as stainless steel, aluminum and titanium, argon gas is used in the welding process. quality standard maximizes it.

The Role of Argon Source in the Manufacturing Industry

In the manufacturing industry, argon sourcehas a critical role in a wide variety of industries that require quality and durable metal workmanship. Especially in sectors such as automotive, aviation, shipbuilding and energy production, argon source provides high performance, is becoming more and more preferred day by day. Metal parts used in these sectors durability, safety and longevity are of great importance. SS Project offers solutions that increase durability in the manufacturing industry with products produced using argon welding. This process extends the life of the products, especially by increasing the strength of metal structures. Argon welding optimizes the weather conditions around the metal, increasing the strength of the weld seams and making them resistant to external factors. In the automotive industry, welding processes on vehicle bodies and engine parts depend on the precision and robustness takes advantage of its features. In the aviation industry, aircraft parts and spacecraft equipment safely Argon welding is preferred for joining. Welding of stainless steel and other metals on ships is done by taking advantage of the cleaning feature of argon welding. In the energy sector, the use of argon welding is common for the safe assembly of pipes and power plant components.

Advantages of Argon Welding

Argon welding attracts attention with the many advantages it provides in the manufacturing industry. Firstly, thanks to this welding technique, the weld seams aesthetics and durability ensures high quality. Oxidation, contamination and metal deformations that occur during welding argon gas Thanks to this it is prevented. This is more than the source durable and long lastingmakes it happen. SS Project's experienced engineer staff offers durability, speed and efficiency advantages in the manufacturing industry, thanks to the superior welding quality provided by argon welding technique. In this way, long-lasting and high-quality products are produced.ique is that it provides a more controlled distribution of heat around the metal. thermal deformation is to get ahead of it. This feature is of great importance, especially in the processing of thin metal parts. Argon gas protects the atmosphere around the weld and ensures that the metal being welded is cleaner. Thus, with lower cost and less margin of error to high quality you can reach. Thanks to the safety, durability and aesthetic benefits provided by this source, argon welding is largely preferred in industrial works.

Methods to Increase Durability with Argon Welding Technique

argon sourceis an important technique that increases durability, and this is often thermal damage achieved by minimizing it. argon gasBy creating an atmosphere around the metal during welding, it prevents oxidation and external factors from damaging the metal surface. In this way, the integration of the weld with the metal becomes stronger and longer-lasting. Keeping the heat effects around the weld to a minimum is of great importance, especially in the processing of sensitive metals. SS Proje is a leader in increasing the durability of the units produced with argon welding technique. Thanks to engineering solutions, the durability of the products is optimized, resulting in high-performance structures even under harsh conditions. the metal being welded increase endurance Another method used is to select appropriate metal fillings. By using compatible fillers according to the type of metal, the welding structural integrity and becomes more resistant to external factors. Technological equipment used in argon welding also increases the quality of the weld, long lasting and safe Allows connections to be made. Today's advanced argon welding machines optimize the efficiency of the weld while performing the function of increasing durability with precise welding seams.

Application Areas of Argon Welding

Argon welding is used in many industrial applications. One of the most common areas of application of this resource automotive industryis. In automobile production, argon welding techniques are used to weld vehicle body parts, safe and sound connections are obtained. In the aviation and space industry, argon welding is also of great importance for the assembly of aircraft parts and spacecraft equipment. Welding processes in the aviation industry high security and meets durability requirements. SS Proje offers robust and long-lasting solutions by using argon welding techniques in different areas such as automotive, aviation and construction sectors. Contributing to the country's economy through exports, the company gains a competitive advantage in the global market. In the shipping industry, argon welding is used especially for the engines and hulls of ships. In the energy sector, argon welding is widely preferred for pipes and various metal structures in large-scale projects such as nuclear power plants and oil refineries. The construction industry is another important area where argon welding can be used. metal structures durability and safetyis provided by argon source. Apart from this, the medical and biomedical industry uses argon welding in the assembly of devices and joining metal parts.

Argon Welding Equipment and Selection

The equipment used in argon welding directly affects the success of the welding. TIG welding machinesis one of the most preferred equipment for argon welding. These machines allow the welding process to be carried out in a precise and controlled manner. Welding torches ensure that the metal is kept at the correct temperature during welding and argon gas allows its effective use. The quality of the argon gas used in the welding process also affects the weld seam. cleanliness and durability effects. Argon gas must have high purity because impurity of the gas can cause contamination of the metal during the welding process. Correct selection of equipment, welding process quality and efficiency direct effects. Regular maintenance of the welding equipment used, preserving the quality of the weld workforce efficiencyincreases. When selecting equipment, the type of metal to be welded, the type of process, and the requirements of the weld should be considered. SS Project works with the latest technology in argon welding equipment. It ensures customer satisfaction with its innovative engineering staff, correct equipment selection and high quality welding processes.

Argon Source Prices and Cost Analysis

Prices of argon welding vary depending on the equipment used and the type of metal being welded. Prices of welding machines may vary depending on their technological features. Advanced models, high precision Although it is preferred for applications that require it, its initial costs are high. SS Project manages to reduce costs and increase efficiency by optimizing the use of argon resources. These savings in manufacturing processes allow economical solutions to be offered in both local and international projects. argon gas Prices vary depending on the size of the area where welding will be done and the amount of gas required for the welding process. Additionally, the argon source provides high quality resourcesIt provides savings to businesses in the long run by reducing maintenance and repair costs. Less error and deformation after the welding process leads to less labor and lower production costs over time. However, the high durability provided by argon welding means less malfunction and more long lasting parts produces. Ultimately, argon welding is more cost-effective and cost-effective in the long term, beyond the initial cost. an efficient option presents.

The Future of Argon Welding in the Manufacturing Industry

SS Project constantly develops argon welding technologies and aims to offer more innovative solutions regarding this technique in the future. In its future projects, it will focus on more environmentally friendly and sustainable production processes through the use of argon resources. The future of argon welding looks very bright with the rapid advancement of technology. New generation welding machines, faster and more precision welding will allow transactions to be carried out. robotic systems Its integration will enable argon welding to become more widespread in production processes. Studies on environmentally friendly welding methods show that argon welding its sustainability will increase and make it preferred in more industries. More effective use of argon source with industrial automation systems, productivity increase will reduce costs. With the diversification of industrial applications, argon welding will begin to be used in more sectors and this technology will further develop.