Powder Transfer Systems

- Blog

- Powder Transfer Systems

Powder Transfer Systems

Table of Contents

- Dust Transfer System - What Is It and How Does It Work?

- In Which Industries Is Dust Transfer Used?

- Pneumatic and Mechanical Dust Transfer Systems - What Are the Differences?

- How to Increase Efficiency in Dust Transfer Systems?

- Why Is Filtration Important in Dust Transfer?

- How Should Maintenance and Cleaning of Dust Transfer Systems Be Performed?

- What Sets SS Proje's Dust Transfer Solutions Apart from Competitors?

Dust Transfer System - What Is It and How Does It Work?

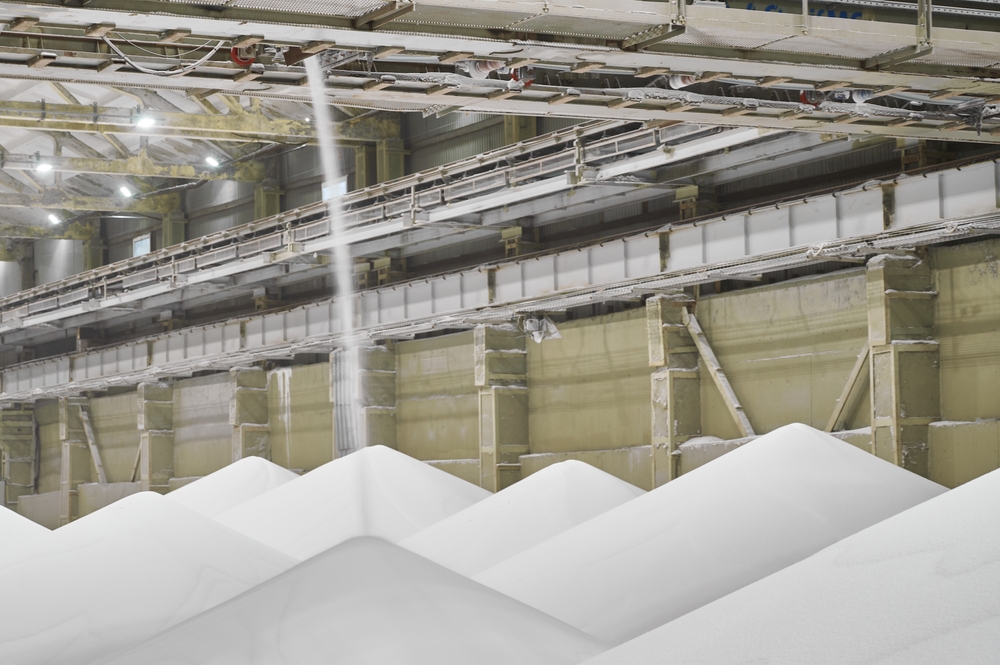

A dust transfer system is a specialized system designed to safely, efficiently, and controllably transport dry, fine particulate materials (e.g., flour, cement, chemical powders) from one point to another in industrial facilities. These systems are typically used to optimize material flow in production processes, prevent environmental dust dispersion, and enhance workplace safety.

Dust transfer systems can be pneumatic (operated by air pressure) or mechanical (using conveyor belts, screws, etc.). Pneumatic systems use air to either pull materials through pipes via vacuum or push them with pressure. This method minimizes dust leakage due to its closed system design. Mechanical systems, on the other hand, utilize rotary valves, screw conveyors, or elevators to physically transport materials.

Factors such as dosing, filtration, and pressure control are critical to the operation of these systems. A well-designed dust transfer system accelerates the production process and contributes to sustainability by preventing harmful dust emissions.

In Which Industries Is Dust Transfer Used?

Dust transfer is an indispensable part of production processes in many industrial industries. These systems play a critical role in the processing, transportation, and storage of dry, fine particulate raw materials. Key industries where dust transfer systems are widely used include food, chemical, pharmaceutical, cement, plastic, paint, glass, and mining industries.

In the food industry, dust transfer systems are preferred for the hygienic and controlled transport of materials like flour, sugar, cocoa, and milk powder. In the chemical industry, the safe transport of flammable or toxic dusts is of vital importance. In pharmaceuticals, high hygiene standards make closed-system dust transfer solutions essential.

In the cement and construction materials industry, durable and high-capacity systems are required to transport large quantities of heavy dusty materials like lime, gypsum, and cement. In the plastic and paint industries, pigments and additives are transported to mixing lines using these systems.

Customized dust transfer systems tailored to each industry’s needs improve production quality while providing significant advantages in terms of workplace safety and environmental protection.

Pneumatic and Mechanical Dust Transfer Systems - What Are the Differences?

Dust transfer systems are divided into two main categories based on material transport methods: pneumatic and mechanical. There are significant differences between these systems, and the appropriate choice depends on the application.

Pneumatic dust transfer systems transport dust through pipelines using air pressure or vacuum power. Their closed system design minimizes environmental dust dispersion. Due to contactless transport, they are widely used in industries like food and pharmaceuticals where hygiene is critical. They also offer the advantage of transporting materials over long distances and complex routes. However, they may have higher energy consumption and relatively higher initial setup costs.

Mechanical dust transfer systems operate using equipment such as screw conveyors, belt systems, or bucket elevators. Since materials are physically transported, these systems can operate with lower energy consumption. They are ideal for short-distance, fixed routes and are commonly used in heavy industry sectors like cement, mining, and construction chemicals.

The advantages and disadvantages of both systems should be evaluated based on process requirements.

How to Increase Efficiency in Dust Transfer Systems?

Efficiency in dust transfer systems is crucial for increasing production capacity and reducing energy and maintenance costs. An efficient system minimizes material loss, prevents environmental dust dispersion, and ensures uninterrupted production flow.

The first step to improving efficiency is proper system design. The transfer method should be selected based on the material’s properties (density, moisture content, particle size). For example, pneumatic systems are preferred for fine and light dusts, while mechanical systems are more effective for heavy and dense materials.

Automation and sensor integration enable real-time monitoring of the system, allowing early intervention for issues like blockages or overloading. Regular maintenance and cleaning are also critical for maintaining system performance; filters, pipes, and rotary valves should be periodically inspected.

Why Is Filtration Important in Dust Transfer?

Filtration in dust transfer systems is critical for both environmental and operational reasons. The primary purpose of filtration is to prevent dust particles generated during transport from dispersing into the environment, thus protecting workers’ health. It also plays a vital role in ensuring efficient system operation and extending equipment lifespan.

Filters prevent dust from escaping pipelines, providing a clean working environment. In sensitive industries like food, chemicals, and pharmaceuticals, filtration systems are essential for meeting hygiene standards. In environments with explosive dusts, improperly designed filtration systems can pose serious safety risks.

Filtration also cleans the air or gas within the system, preventing damage to vacuum pumps, fans, and other equipment. This reduces maintenance costs and enhances system performance. Companies like SS Proje provide application-specific filtration systems that ensure compliance with legal requirements and contribute to sustainable production processes.

How Should Maintenance and Cleaning of Dust Transfer Systems Be Performed?

Regular maintenance and cleaning are essential for ensuring that dust transfer systems operate efficiently, safely, and with a long lifespan. Accumulated dust in these systems can lead to blockages, efficiency losses, and even explosion risks. Therefore, both mechanical and pneumatic systems require a periodic maintenance plan.

First, filter systems should be checked at regular intervals and replaced if necessary. Clogged filters restrict airflow, reducing system performance. Pipes, screws, rotary valves, and conveyor components should also be regularly cleaned to remove dust buildup. During cleaning, the system must be completely shut down, and operations should comply with workplace safety regulations.

Sensors, motors, and control panels should also be inspected as part of maintenance. Early detection of wear, loosening, or electrical faults can reduce downtime and costs.

What Sets SS Proje's Dust Transfer Solutions Apart from Competitors?

SS Proje stands out in the industry with its innovative, customized, and high-efficiency dust transfer solutions. The company designs each project tailored to the facility’s structure, the characteristics of the material being transported, and production requirements, ensuring maximum performance and minimal energy consumption.

Its primary distinction from competitors lies in combining process engineering expertise with practical application. SS Proje not only supplies equipment but also professionally manages system installation, commissioning, automation integration, and ongoing technical support.

Additionally, its closed system designs prevent dust leakage, high-precision dosing solutions, and safety measures against explosion risks prioritize workplace safety and environmental protection.

With its R&D and engineering infrastructure, SS Proje offers high-quality, cost-effective solutions through local production, adopting a customer-focused and long-term partnership approach that delivers exceptional service.