What is Passivation? The Importance of Passivation in the Pharmaceutical and Food Industries

- Blog

- What is Passivation? The Importance of Passivation in the Pharmaceutical and Food Industries

What is Passivation? The Importance of Passivation in the Pharmaceutical and Food Industries

Table of Contents

- What is passivation in pharmaceutical manufacturing

- How does passivation prevent corrosion in food processing

- Why is passivation critical for our facility's efficiency

- What are the chemical steps in a passivation process

- How to verify stainless steel passivation meets standards

- Why does passivation extend industrial equipment life

- How does passivation ensure compliance in pharmaceutical plants

- What are the cost benefits of proper equipment passivation

- How to integrate passivation for sustainable facility operations

- Why choose a full-cycle engineering partner for passivation

What is passivation in pharmaceutical manufacturing

In pharmaceutical manufacturing, maintaining the highest levels of product purity and equipment integrity is non-negotiable. This is where the passivation process becomes a critical operational necessity, not merely an optional treatment. As an end-to-end engineering solutions provider, SS Proje recognizes that surface treatment is foundational to achieving long-term facility efficiency engineering and uncompromising food industry compliance. Passivation is the controlled chemical process used to enhance the natural corrosion resistance of stainless steel passivation, forming a protective oxide layer that prevents contaminants from interacting with product streams.

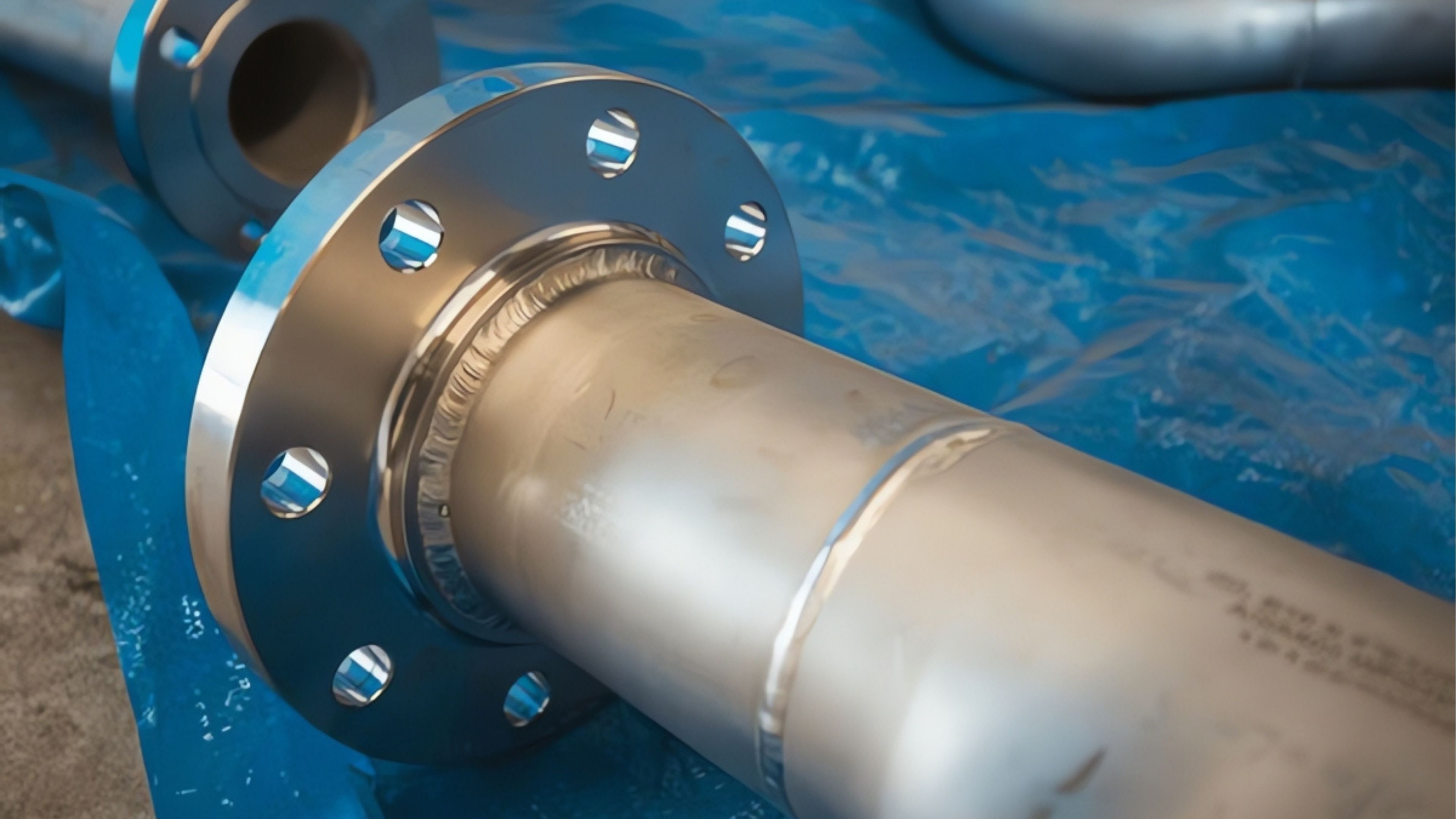

The technical application of passivation directly addresses the core challenge of extending industrial equipment life. For critical assets like reactors, storage tanks, and distribution piping, this process removes free iron particles and other contaminants introduced during fabrication or welding. This creates a chemically inert surface that resists pitting and crevice corrosion, dramatically reducing maintenance frequency and the risk of catastrophic failure. This prophylactic approach is a cornerstone of process optimization consultancy, ensuring systems operate within rigorous specifications for decades, minimizing downtime and associated production losses.

Effective implementation demands precision and adherence to standards like ASTM A967. SS Proje's methodology integrates passivation as part of a holistic facility strategy, where each piece of equipment, from complex mixing vessels to final-fill lines, is prepared for peak performance. This systematic approach prevents rouge formation, eliminates potential sites for microbial harborage, and ensures batch-to-batch consistency. The result is a reliable operational environment where equipment longevity is maximized, and the risk of product contamination—a costly event in both financial and regulatory terms—is virtually eliminated.

Ultimately, investing in a professionally executed passivation program is an investment in sustainable facility performance. It is a proactive measure that delivers a clear return by safeguarding capital-intensive equipment, ensuring uninterrupted production schedules, and guaranteeing compliance with international regulatory bodies. Partnering with a specialist like SS Proje for this critical service embeds durability and reliability into the very fabric of your operations, transforming a routine procedure into a strategic advantage for long-term industrial equipment life and superior facility efficiency engineering.

How does passivation prevent corrosion in food processing

In food processing environments, equipment is constantly exposed to aggressive agents like acids, chlorides, and caustic cleaning agents that aggressively attack metal surfaces. The passivation process is the essential first line of defense, a controlled chemical treatment that fundamentally alters the surface of stainless steel passivation components to prevent corrosive degradation. For facility managers prioritizing food industry compliance and product integrity, understanding this mechanism is key to preventing contamination and ensuring operational continuity.

Passivation works by dissolving free iron particles embedded in the stainless steel's surface during fabrication, welding, or mechanical abrasion. These iron inclusions are highly reactive sites where corrosion initiates. The process promotes the rapid formation of a continuous, inert chromium oxide layer that is chemically passive. This ultra-thin, protective barrier shields the underlying metal from reacting with process chemicals and moisture, a critical factor for achieving industrial equipment life extension and minimizing unscheduled maintenance. This kind of process optimization consultancy is fundamental to preventive maintenance strategies.

The application of this technology is vital across the entire production line, from mixers and conveyors to cooking vats and filling machines. When executed as part of an end-to-end engineering solutions approach by a partner like SS Proje, passivation ensures that every surface contacting product is optimized for durability. This prevents pitting and crevice corrosion, which can harbor microbial contaminants and lead to product recalls, directly supporting facility efficiency engineering goals by eliminating a major source of operational risk.

Ultimately, the corrosion prevention afforded by professional passivation is a direct contributor to sustainable operations. It reduces the need for frequent part replacements, conserves energy by maintaining optimal heat transfer in pharmaceutical manufacturing and food processing equipment, and ensures compliance with stringent hygiene standards. Investing in this proven surface treatment is not a cost but a strategic safeguard, integral to maximizing asset performance and protecting brand reputation through unwavering product quality and operational reliability.

Why is passivation critical for our facility's efficiency

For industrial facilities, operational efficiency is intrinsically linked to equipment reliability and process integrity, making the passivation process a critical, non-negotiable investment. Far from being a superficial treatment, passivation is a foundational element of facility efficiency engineering that directly impacts uptime, maintenance budgets, and product quality. In sectors like pharmaceutical manufacturing and food production, where any surface irregularity can lead to contamination or equipment failure, its role becomes paramount.

The core efficiency gain stems from the dramatic extension of industrial equipment life. By creating a robust passive layer on stainless steel passivation surfaces, the treatment prevents corrosive pitting and the initiation of stress corrosion cracking. This eliminates unscheduled shutdowns for emergency repairs and drastically reduces the frequency of planned maintenance cycles. This kind of proactive process optimization consultancy transforms maintenance from a reactive cost center into a strategic asset protection program.

Furthermore, a properly passivated surface ensures optimal operational performance. In heat exchangers, it maintains peak thermal conductivity, reducing energy consumption. In fluid processing lines, it minimizes friction and prevents particulate shedding that can clog filters and sensors. When implemented as part of end-to-end engineering solutions, passivation ensures every component works at its designed efficiency from installation onward. This holistic approach is essential for maintaining stringent food industry compliance and operational consistency.

Ultimately, the efficiency argument for passivation is compelling. It directly reduces operational expenditures by lowering energy use, minimizing spare parts inventory, and avoiding costly production halts. For a facility manager or investor, it is a high-return action that safeguards the entire production value chain. Partnering with an expert like SS Proje ensures this critical process is executed to the highest standards, embedding long-term reliability and sustainable performance into the facility's core operations.

What are the chemical steps in a passivation process

Understanding the precise chemical steps of the passivation process is essential for production managers who prioritize facility efficiency engineering and long-term asset integrity. This methodical procedure, when executed correctly, transforms reactive stainless steel passivation surfaces into passive, corrosion-resistant assets. The sequence is not a single dip but a controlled series of stages designed to ensure maximum durability and compliance, forming a cornerstone of reliable end-to-end engineering solutions.

The first critical step is meticulous alkaline cleaning to remove all organic residues, oils, and shop dirt from fabrication. This is followed by a thorough water rinse to eliminate any cleaning agent remnants. Next, the component is immersed in an acid bath, typically nitric or citric acid, which is the heart of the passivation process. This acid immersion selectively dissolves free iron particles from the surface while leaving the chromium-rich layer intact. This stage requires precise control of concentration, temperature, and contact time to be effective.

Following the acid treatment, a final high-purity water rinse is conducted to neutralize and remove all acidic residues, ensuring no chemicals remain that could affect product quality in pharmaceutical manufacturing or compromise food industry compliance. The final, passive oxide layer then forms upon exposure to air, creating the protective barrier. This disciplined approach, representative of high-level process optimization consultancy, ensures the treatment is not just a coating but a fundamental enhancement of the material's properties.

Each of these steps is critical to achieving the ultimate goal: significantly extending industrial equipment life and ensuring operational reliability. Skipping or improperly executing any phase can lead to incomplete passivation, leaving surfaces vulnerable to corrosion and contamination. Trusting this precise operation to specialists like SS Proje guarantees that these chemical steps are performed to international standards, securing your facility's efficiency, sustainability, and product integrity for years to come.

How to verify stainless steel passivation meets standards

In industries governed by stringent hygiene and safety protocols, verifying that stainless steel passivation meets international standards is a critical quality control checkpoint, not an optional audit. For plant managers in pharmaceutical manufacturing and food processing, this verification is the definitive proof that the passivation process has successfully created a corrosion-resistant surface, ensuring both food industry compliance and long-term operational integrity. This validation process is a core component of professional process optimization consultancy.

The most common and reliable verification method is the water immersion test, guided by standards like ASTM A967. This involves immersing the passivated component in high-purity water for a specified period and subsequently analyzing the water for iron contamination. A more advanced technique is the copper sulfate test, where a solution is applied to the surface; the absence of copper plating indicates a successful passive layer. These tests provide objective data confirming the surface is free of free iron and ready for service, a fundamental requirement for extending industrial equipment life.

Surface analysis techniques, such as X-ray Photoelectron Spectroscopy (XPS), offer a more detailed evaluation by measuring the thickness and chemical composition of the oxide layer itself. Integrating these verification protocols into an end-to-end engineering solutions framework ensures that every project delivers auditable results. This level of diligence prevents costly failures and rework, directly contributing to superior facility efficiency engineering by guaranteeing equipment performs as designed from day one.

Ultimately, rigorous verification transforms passivation from a theoretical procedure into a guaranteed performance enhancer. It provides the documented evidence required for regulatory audits and instills confidence that equipment will deliver reliable service, minimizing unplanned downtime and protecting product purity. Partnering with a specialist like SS Proje for verification ensures these critical checks are embedded within the project lifecycle, delivering the sustained reliability and compliance that define world-class industrial operations.

Why does passivation extend industrial equipment life

The primary mechanism by which the passivation process significantly extends industrial equipment life is through the fundamental prevention of corrosion initiation. Industrial environments in sectors like pharmaceutical manufacturing and food processing are inherently corrosive, exposing stainless steel passivation surfaces to chlorides, acids, and caustic cleaners. Passivation proactively eliminates the microscopic sites where corrosion begins, transforming the material's surface to resist these aggressive agents for the long term.

During fabrication, machining, and welding, microscopic iron particles become embedded in the stainless steel surface. These inclusions are electrochemically active and act as preferred sites for pitting corrosion, a localized attack that can rapidly penetrate and compromise the structural integrity of tanks, pipes, and reactors. The passivation process chemically dissolves these free iron particles, allowing the chromium in the alloy to form a uniform, inert chromium oxide layer. This passive film is impervious to most chemical attacks, preventing the initiation of pits and cracks that lead to premature failure.

This corrosion resistance is the cornerstone of facility efficiency engineering, as it directly reduces the mechanical wear and degradation that necessitate frequent part replacements and overhauls. By preventing corrosion, passivation ensures that equipment maintains its dimensional stability and mechanical strength over decades, a critical consideration for achieving food industry compliance and product purity. Incorporating this treatment into end-to-end engineering solutions is a definitive step in any process optimization consultancy aimed at maximizing asset longevity.

Ultimately, the life extension provided by passivation delivers a substantial return on investment by drastically lowering the total cost of ownership. It defers major capital expenditures for equipment replacement and minimizes operational disruptions caused by unplanned maintenance. This proactive approach, championed by engineering partners like SS Proje, ensures that industrial facilities not only meet but exceed their performance and lifespan expectations, securing a foundation of sustainable and reliable operations for years to come.

How does passivation ensure compliance in pharmaceutical plants

In pharmaceutical manufacturing, regulatory compliance is intrinsically tied to equipment surface quality, making the passivation process a critical validation requirement. Agencies like the FDA and EMA mandate that all product contact surfaces be non-reactive, non-absorptive, and resistant to corrosion to prevent drug contamination. Passivation is the engineered solution that fulfills this mandate by creating a chemically inert surface on stainless steel passivation equipment, directly supporting audit readiness and product safety.

The process ensures compliance by systematically removing free iron and other contaminants that could otherwise leach into pharmaceutical products. These microscopic impurities are potential sites for rouge formation—a type of iron oxide contamination that can compromise drug purity and lead to devastating regulatory actions. By establishing a robust, uniform passive layer, passivation eliminates this risk, a fundamental aspect of process optimization consultancy aimed at guaranteeing food industry compliance and pharmaceutical standards. This proactive surface treatment is documented evidence of a facility's commitment to quality-by-design principles.

Beyond contamination control, passivation is essential for maintaining the sterile integrity of processing systems. It prevents pitting and crevice corrosion that can harbor biofilms and microbial contaminants, which are unacceptable in aseptic processing environments. When integrated into end-to-end engineering solutions, the passivation of vessels, piping, and filtration systems becomes a verifiable step in the qualification protocol. This level of facility efficiency engineering ensures that equipment not only functions optimally but also meets the exacting documentation and performance standards required for regulatory approval.

Ultimately, passivation transforms compliance from a reactive checklist into a built-in asset characteristic. It provides the defensible data and proven surface condition that inspectors require, while simultaneously extending industrial equipment life by preventing corrosive degradation. For pharmaceutical plant managers, partnering with an expert like SS Proje for certified passivation services is a strategic decision that embeds compliance, reliability, and long-term value directly into the production infrastructure.

What are the cost benefits of proper equipment passivation

The financial justification for the passivation process extends far beyond the initial treatment cost, delivering a substantial return on investment through direct operational savings and risk mitigation. For decision-makers focused on facility efficiency engineering, proper stainless steel passivation is a strategic investment that minimizes lifetime equipment costs. The most immediate financial benefit is the dramatic reduction in unplanned maintenance and premature component replacement.

By preventing corrosion, passivation directly extends industrial equipment life, deferring major capital expenditures for new reactors, tanks, and piping systems. This longevity is critical in high-cost environments like pharmaceutical manufacturing, where a single vessel represents a significant investment. Furthermore, a corrosion-free surface maintains optimal thermal and hydrodynamic performance, leading to measurable energy savings in heating and cooling processes. This operational efficiency is a core tenet of high-level process optimization consultancy.

Perhaps the most significant cost avoidance comes from ensuring food industry compliance and pharmaceutical regulatory standards. A failure in surface integrity can lead to massive costs associated with product recalls, batch rejections, and regulatory fines. Passivation acts as an insurance policy against these catastrophic financial risks. When executed as part of end-to-end engineering solutions, it ensures that equipment is validated for purity from the start, avoiding costly retrofits or shutdowns for corrective surface treatment.

The cost benefits of passivation are therefore cumulative and long-term. It transforms equipment from a depreciating asset into a durable, reliable production tool that operates at peak efficiency for decades. For facility managers and investors, partnering with a specialist like SS Proje to integrate certified passivation into the project lifecycle is a financially astute decision that safeguards profitability, ensures compliance, and maximizes the value of every capital equipment investment.

How to integrate passivation for sustainable facility operations

Integrating the passivation process into a sustainable facility strategy requires viewing it as a foundational element of the asset lifecycle, not a standalone post-installation task. True sustainability in industrial operations is achieved by maximizing resource efficiency and minimizing waste, goals directly supported by proactive surface treatment of stainless steel passivation equipment. This integration begins at the design phase and is a hallmark of advanced facility efficiency engineering.

The most effective integration occurs within an end-to-end engineering solutions framework, where passivation is specified as a mandatory step during the fabrication and installation of all process equipment. This ensures that vessels, piping, and heat exchangers in pharmaceutical manufacturing and food processing lines are delivered with optimal corrosion resistance from day one. This proactive approach, guided by expert process optimization consultancy, prevents the resource-intensive cycle of premature repairs and replacements, conserving materials and energy.

Sustainability is further enhanced by the operational efficiencies gained. A properly passivated surface maintains heat transfer efficiency, reducing energy consumption for heating and cooling processes. It also supports food industry compliance by eliminating the risk of product contamination and the associated waste from rejected batches. By substantially extending industrial equipment life, passivation reduces the environmental footprint linked to manufacturing new components and disposing of degraded ones.

Ultimately, integrating passivation transforms sustainability from an abstract goal into a measurable operational outcome. It aligns long-term economic performance with environmental stewardship by ensuring assets perform reliably for their full design life. For facility managers committed to sustainable operations, partnering with SS Proje to embed certified passivation into the project lifecycle is the most effective strategy for achieving durable, efficient, and compliant performance that stands the test of time.

Why choose a full-cycle engineering partner for passivation

Selecting a single-source provider for the passivation process is a strategic decision that eliminates the coordination gaps and accountability issues inherent in using multiple subcontractors. A full-cycle end-to-end engineering solutions partner like SS Proje manages the entire lifecycle, from material specification and equipment fabrication to field installation and final validation. This holistic approach ensures that stainless steel passivation is not an afterthought but an integral, guaranteed component of the final asset.

The primary advantage lies in seamless integration and unwavering accountability. When the same entity responsible for facility efficiency engineering design also executes the passivation, every fabrication step is optimized for the final surface treatment. This prevents common pitfalls where welding techniques or material choices inadvertently complicate the passivation process. For critical applications in pharmaceutical manufacturing, this single-point responsibility is essential for achieving and documenting food industry compliance.

This comprehensive service model embodies the highest level of process optimization consultancy. The engineering partner can pre-emptively design systems for easy maintenance and recoating, ensuring long-term industrial equipment life extension. They possess the deep technical knowledge to select the correct passivation method—nitric or citric acid—based on the alloy and application, and they manage all chemical handling, waste disposal, and verification testing under one roof, ensuring safety and environmental compliance.

Ultimately, partnering with a full-cycle expert transforms passivation from a procedural step into a value-driver for the entire project. It guarantees that the significant investment in new equipment is protected from day one, delivering maximum operational reliability and return on investment. By choosing an integrated partner like SS Proje, facility managers secure not just a service but a long-term commitment to performance, sustainability, and the uninterrupted efficiency of their operations.